BMW has started production of new three- and four-cylinder engines at its Hams Hall plant near Birmingham in the UK, following the completion of a large investment program.

The plant now has brand-new production lines and will machine over one million components for the first time this year as supply will extend to other plants in the Group.

Thanks to the investment project, which was part of £750 million that has been spent across BMW Group’s UK manufacturing sites, the Hams Hall site has become a state-of-the-art facility, capable of producing the next generation of engines and secured a long-term future for itself.

The engines and machined components manufactured at BMW Plant Hams Hall are fitted to a wide range of cars including the new MINI Clubman and the new BMW 7 Series.

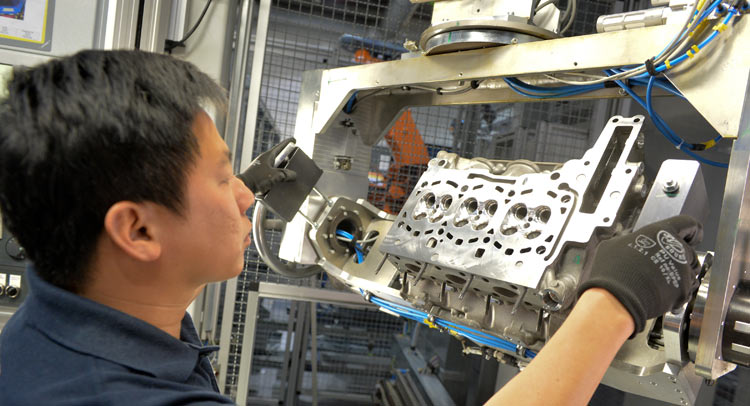

“The transformation in our plant has been huge. Over the last few years we have completely re-developed our two main production areas and installed over 600 brand-new pieces of equipment and machinery,” said Plant Director, Markus Fallboehmer.

The Hams Hall plant now operates alongside other plants in Germany and Austria, all producing the same new family of three-, four- and six-cylinder petrol and diesel engines ranging from 1.5 to 3.0 liters. The new generation engines have a standard design, a high number of similar parts and a uniform process for manufacture.

The facility started building a small number of new engines last year. The three-cylinder BMW TwinPower Turbo technology 1.5-liter petrol engines are hand-built exclusively at Hams Hall on a special production line for the BMW i8.