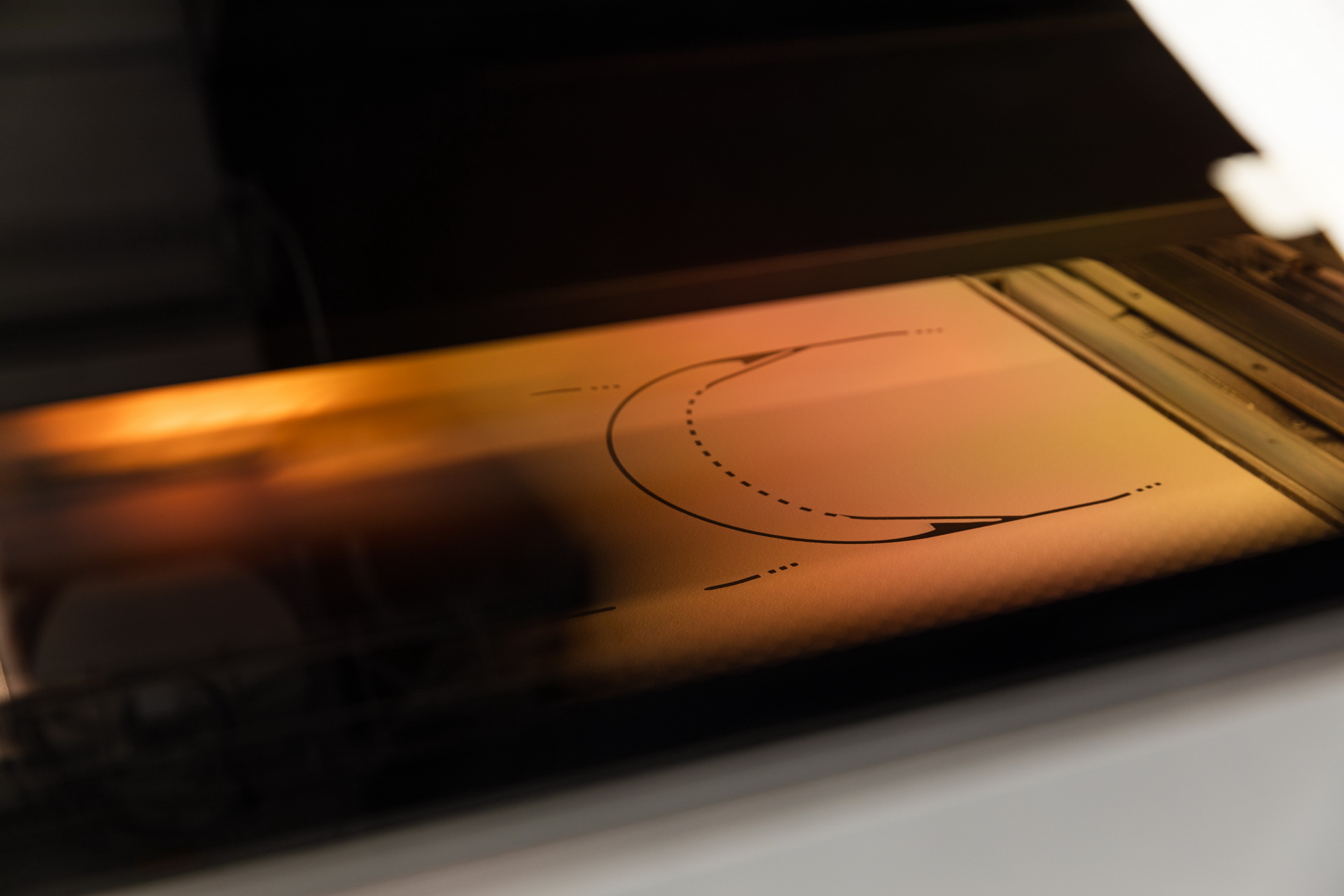

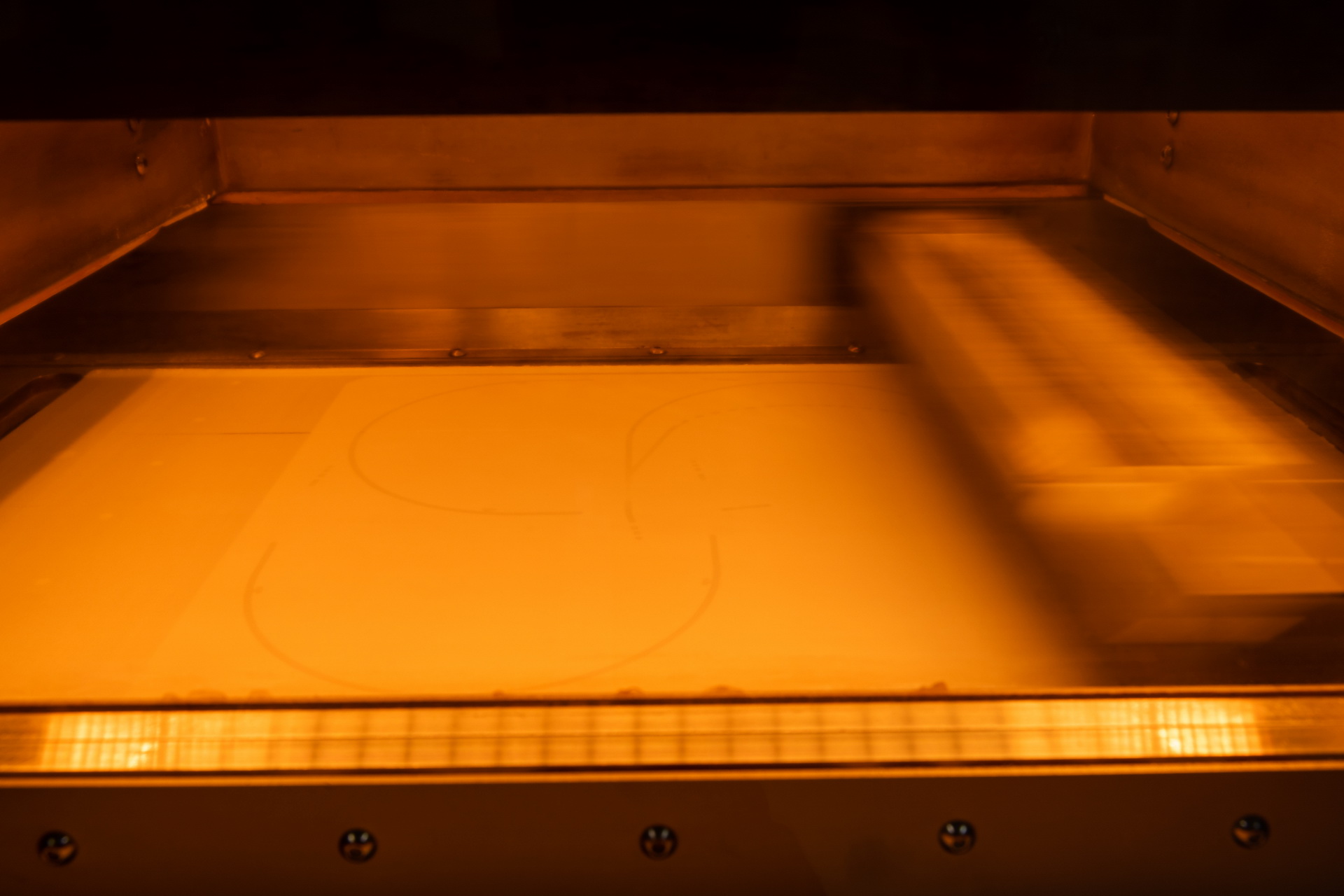

Jaguar Land Rover will use its rapid prototype 3D-printing facility to produce protective visors for key workers, using CAD design expertise.

The design has been developed in consultation with a team of NHS healthcare professionals, with the visors themselves being reusable and of course, NHS-approved. JLR aims to make 5,000 visors per week for NHS trusts across the UK.

Pre-trials have already taken place prior to the British carmaker starting assembly in Warwickshire on March 31.

Read Also: The Lamborghini Of Face Masks Are Being Made In Sant’Agata Bolognese

“It’s been a real team effort, we’ve trialled different materials and improved the design over several iterations in consultation with real doctors and nurses on the frontline – this has allowed us to create something unique and truly fit-for-purpose,” said Ben Wilson, additive manufacturing and prototype design manager.

“While this is a small effort, it is vital we help as many people as we can by utilising our resources. Collaborative teams working at Jaguar Land Rover, along with the wider computer-aided design and 3D printing community will continue to do what we can to help healthcare workers.”

By using rapid prototype technology, engineers were able to create several designs in under a week, allowing medical staff to offer feedback. JLR now intends to make these open source CAD design files available to Additive Manufacturers and suppliers.

Each face visor has been designed to be reusable, and can be easily dismantled and cleaned before being utilized again. In charge of assembly are four Jaguar Land Rover employees, located in a specially designed clean area.