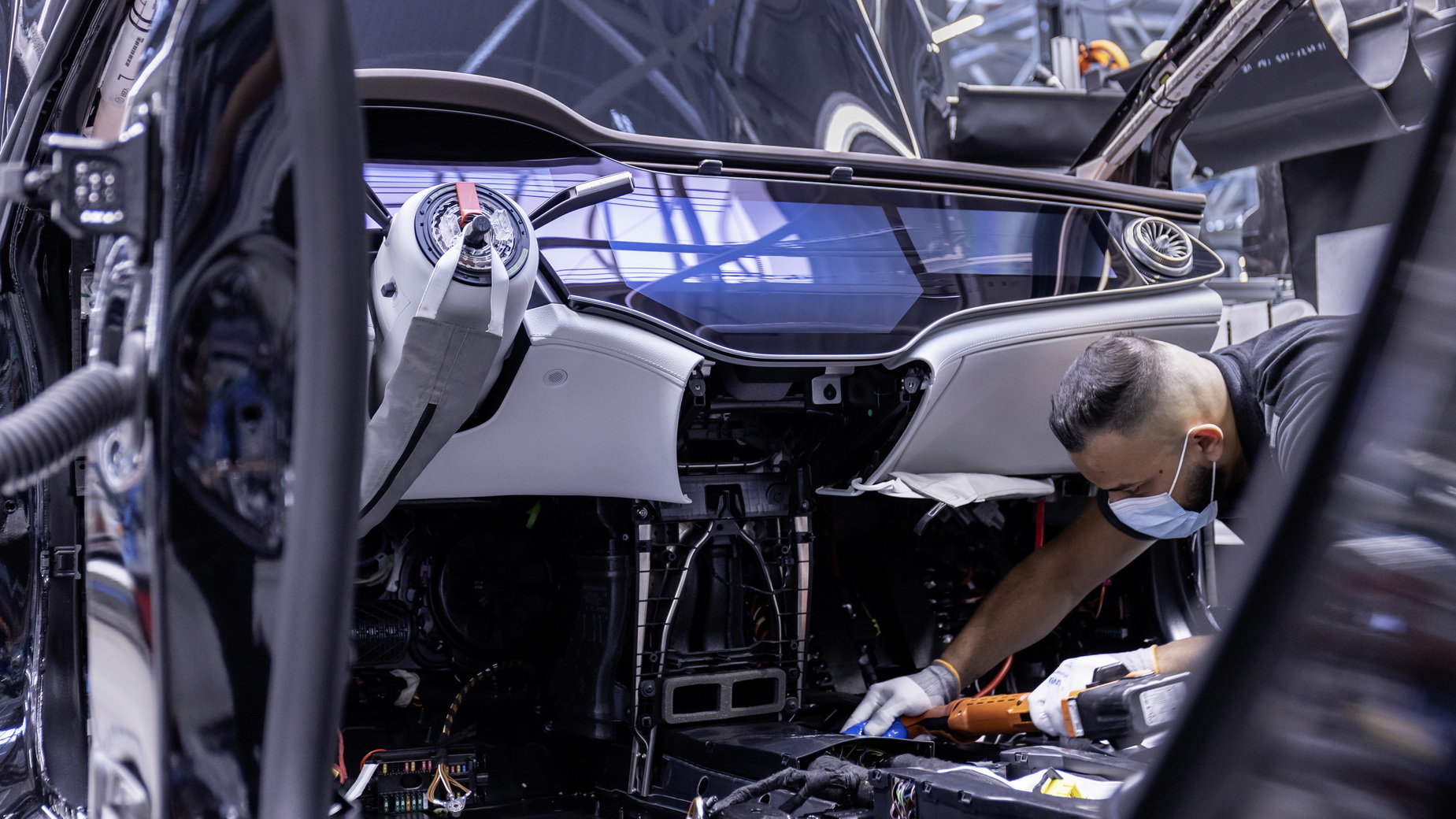

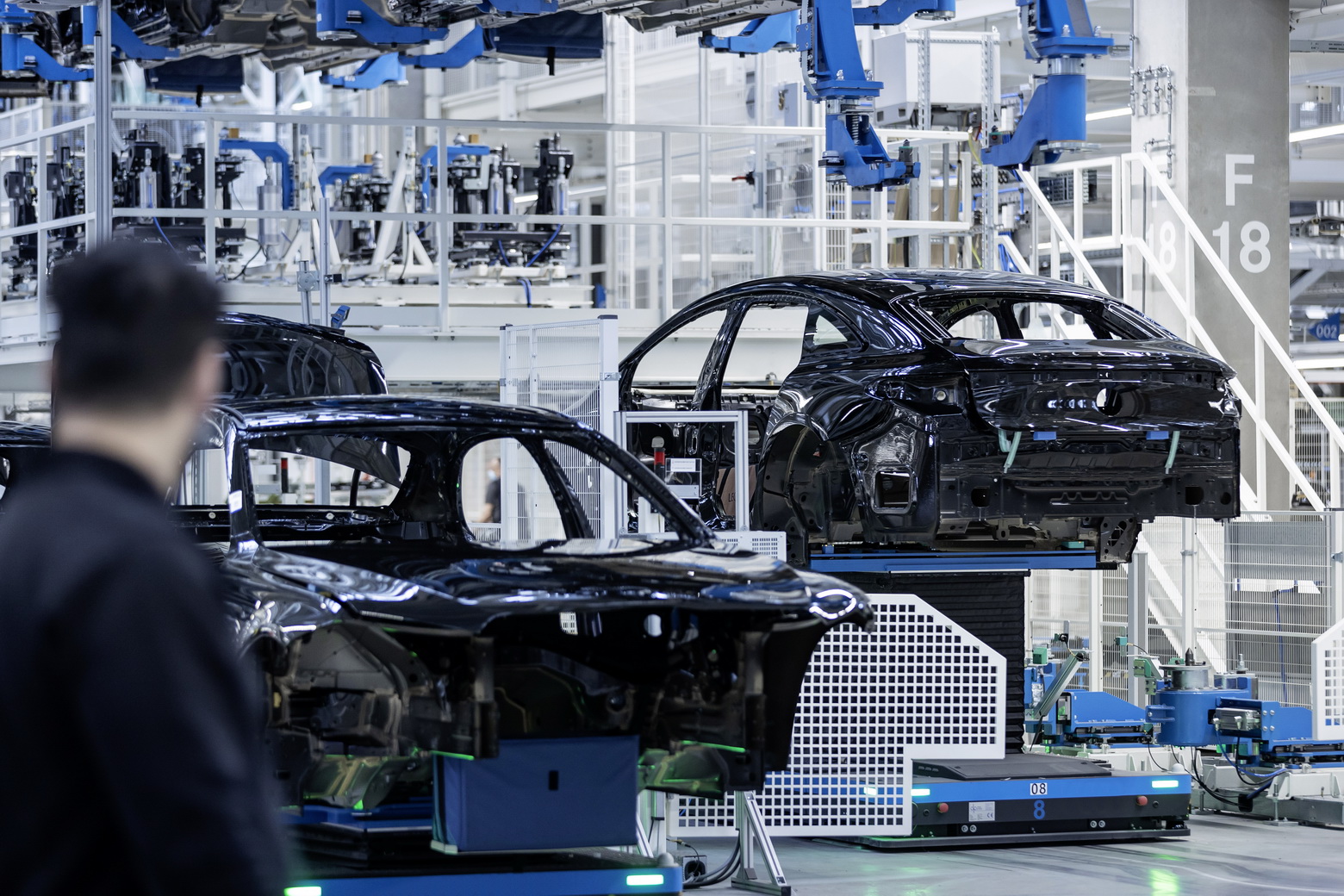

Mercedes-Benz has started assembling the EQS at the Sindelfingen plant in Germany. The company’s flagship electric sedan comes to life at Factory 56, next to the standard and long wheelbase versions of the Mercedes-Benz S-Class and the Mercedes-Maybach S-Class.

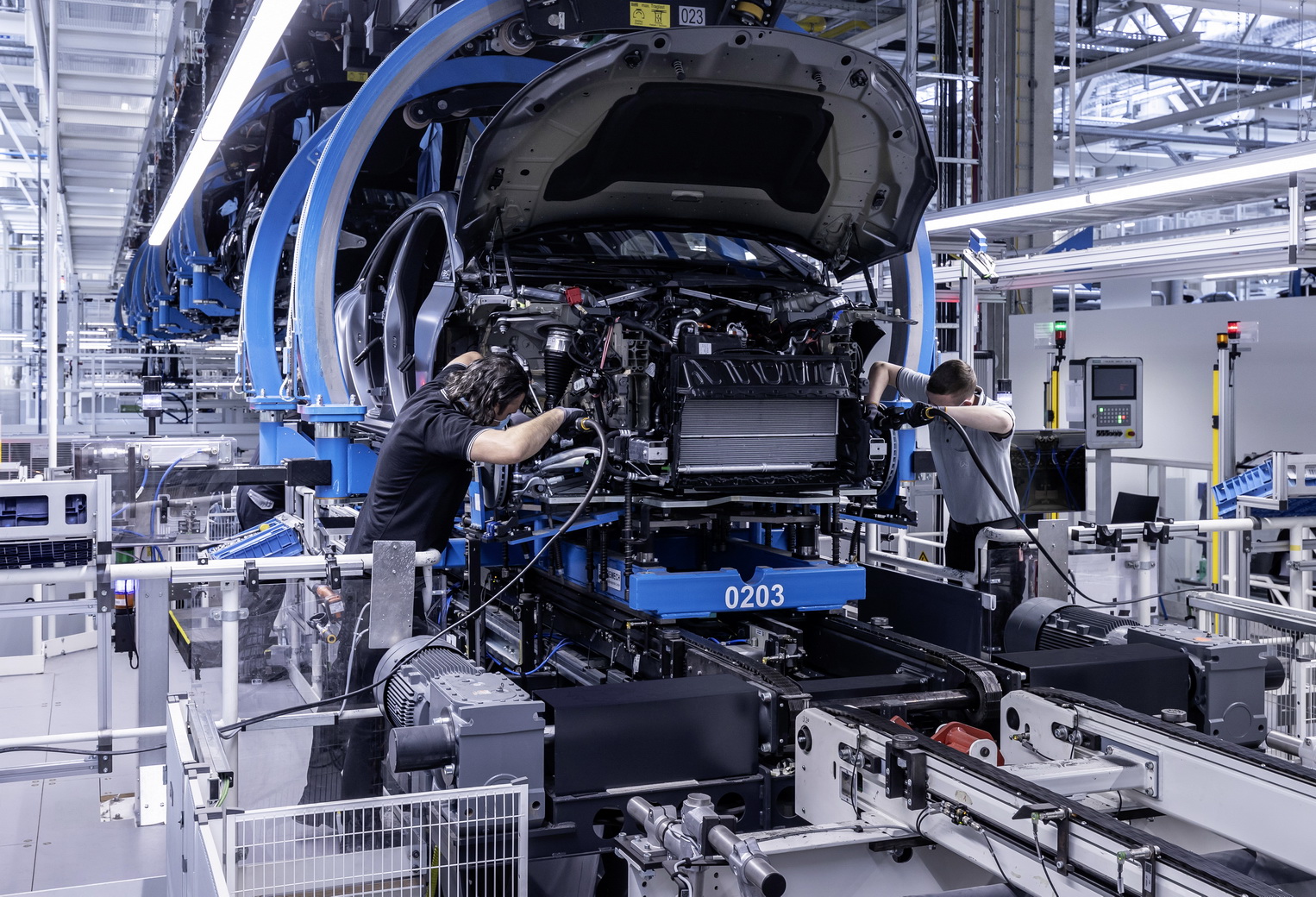

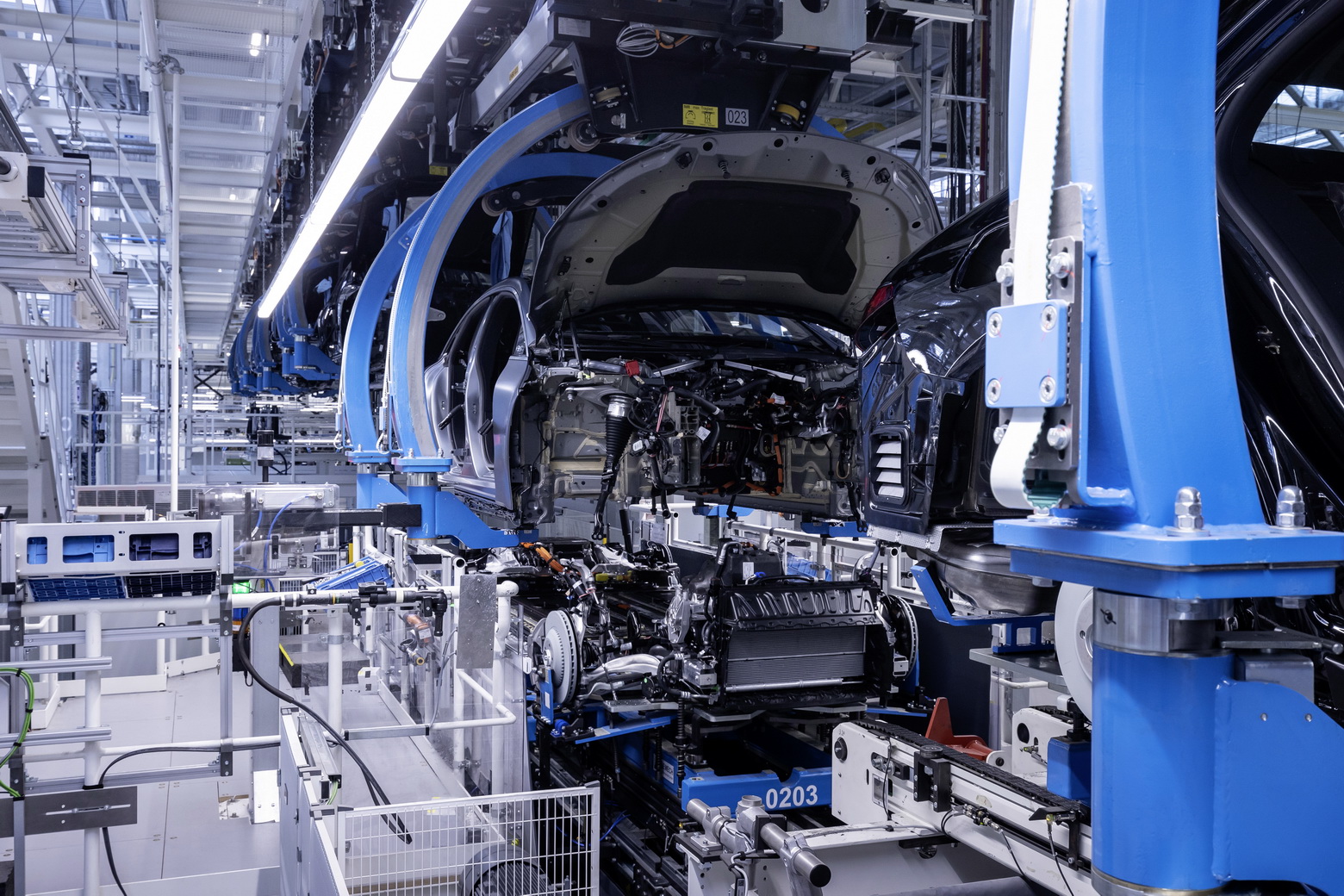

Home to more than 1,500 employees, the site is highly flexible thanks to high levels of digitalization, as it can assemble different models and drivetrains. The powertrains and their respective bodies can be put together on the same line, thus maximizing efficiency. For instance, the body of the EQS is connected to the drive system in the area known as the ‘Fullflex Marriage’.

Video: Unboxing The Tech That Makes Mercedes’ EQS the New S-Class Of Electric Cars

“Our new all-electric luxury saloon EQS sets new standards, with a range of 770 km (478 miles) according to WLTP. At the same time, the EQS stands for sustainability along the entire value chain: from development through purchasing, production and the charging process to recycling”, said Mercedes-Benz Member of the Board of Management, Markus Schafer. “The EQS is thus a milestone on the way to our Ambition 2039, with which Mercedes-Benz is working intensively on a CO2-neutral new car fleet.”

A true S-Class from the future, the EQS is built around a new EV-dedicated platform and is almost as big as the long wheelbase S-Class. It will launch with a 329 HP single-motor in the 450 RWD variant, and a dual-motor set-up with 516 HP in the AWD 580. The former does the 0-62 mph (0-100 km/h) in 6.2 seconds and the latter in 4.3 seconds. And if this isn’t enough, Mercedes has already announced that a 715 HP model will follow, presumably badged as an AMG.