It’s been a year since the Volkswagen Group revealed its brand-new MQB platform (“Modularer Querbaukasten”, which is German for Modular Transverse Matrix) to the world.

This new architecture, which debuted on the third-gen Audi A3, will not be used only for the group’s C-segment cars, like the VW Golf, Seat Leon, Skoda Octavia etc. but in other categories as well. In fact, it may be the German group’s biggest weapon in achieving its goal to become the number one manufacturer globally, outselling current leader Toyota, by 2018 – or even sooner.

The “global car”, i.e. the same design that can be sold, with minor modifications, in all world markets is something touted from time to time by many manufacturers. Yet, VW is the first automaker that may actually achieve it thanks to Ulrich Hackenberg, an auto engineer who had reportedly pitched his idea to other manufacturers until VW eventually bought it.

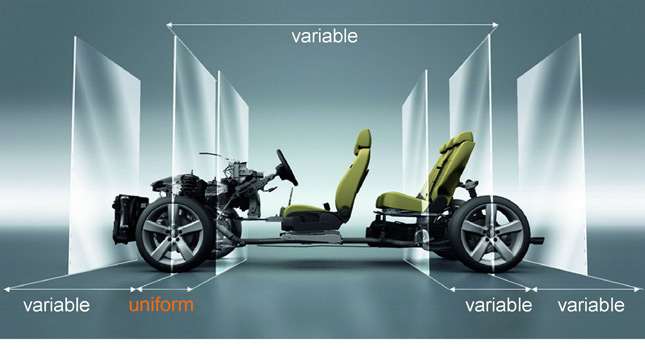

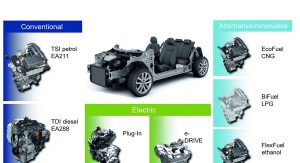

The basic principle is simple: build an architecture that’s flexible enough to accommodate anything, from a supermini like the Polo to a seven-seat SUV like the one VW will introduce in the U.S. market in 2015. This is more than just the chassis, though, as it concerns a common component strategy far beyond anything ever implemented until now.

IHS Consulting managing director Michael Robinet says that the MQB platform “could be the single most important automotive initiative of the past 25 years. It really changes the game.”

Robinet’s company estimates that VW’s plan is to increase its global sales to 10 million units or more, with nearly two out of three cars sold (6.3 billion) being built on the MQB platform.

Rivals have certainly taken notice of this new strategy. “We’d be crazy not to”, a senior Ford official told Reuters, while a Toyota executive conceded that “there’s no doubt we’ve fallen behind. We have not even begun to make the fundamental structural changes that VW has”. Both spoke on anonymity terms due to the sensitive nature of the subject.

Both analysts and the auto industry believe that the MQB could prove to be as revolutionary as Henry Ford’s production line or Toyota’s “just-in-time” system. VW has been working on it since 2007 and, along with its implementation over the next four years, its investment will reach nearly US$70 billion. Considering that Morgan Stanley estimates it will result in annual gross savings of US$19 billion by 2019, that’s money well spent.

Since the MQB is designed for models with a transversely-mounted engine, VW also has two other aces up its sleeve: the MLB platform, for models with longitudinally-mounted engines, and the MSB, for premium rear- and all-wheel drive models from Porsche, Lamborghini, Bentley and, probably, Audi too.

So that makes a total of three modular platforms, each designed from the outset to use a huge set of common components and be able to accommodate gasoline, diesel and even hybrid powertrains.

“Modular platforms have grown beyond the technology (alone) to become a management tool which helps support the brands’ development. The toolkits help the brands to preserve their character and sharpen their individuality”, said Hackenberg, who is now the development chief for the Volkswagen brand.

There’s only one risk: the huge volumes of common components also mean that, if there is a fault in a certain part, it will result in a huge global recall campaign; one that may make even the one implemented by Toyota look tame in comparison.

By Andrew Tsaousis

Story References: Reuters

PHOTO GALLERY