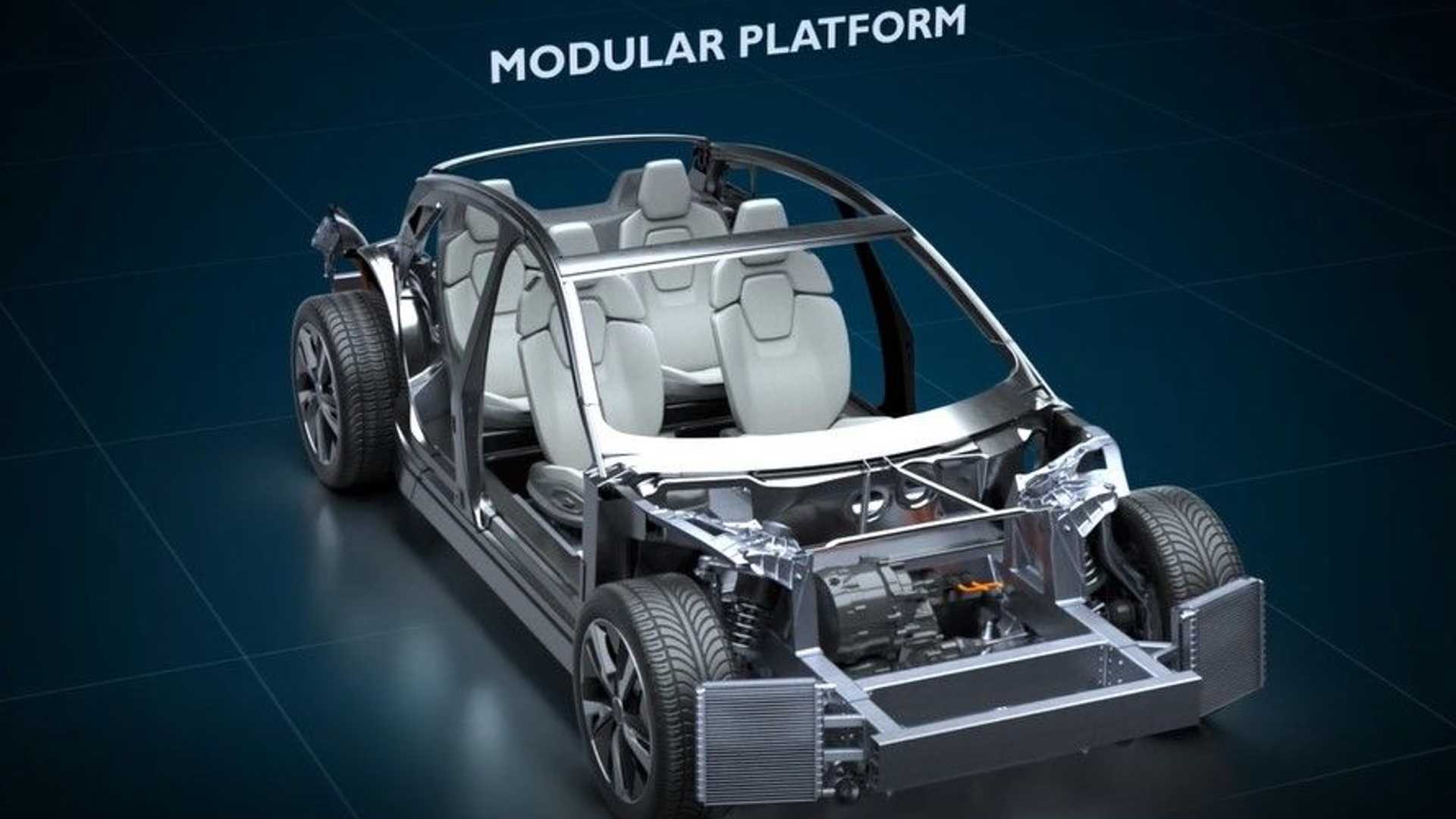

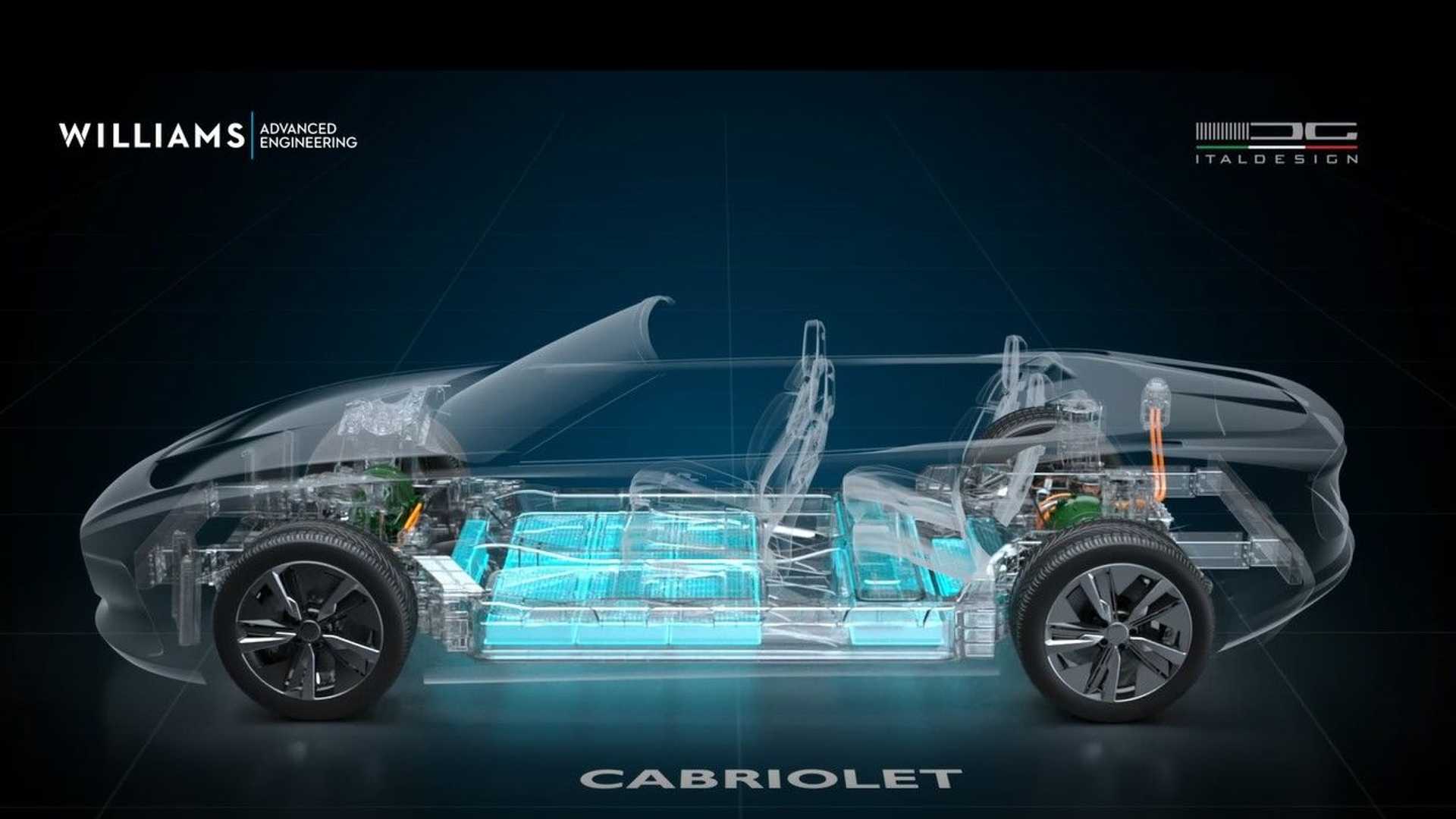

Williams Advanced Engineering and Italdesign have partnered to create an advanced electric vehicle platform.

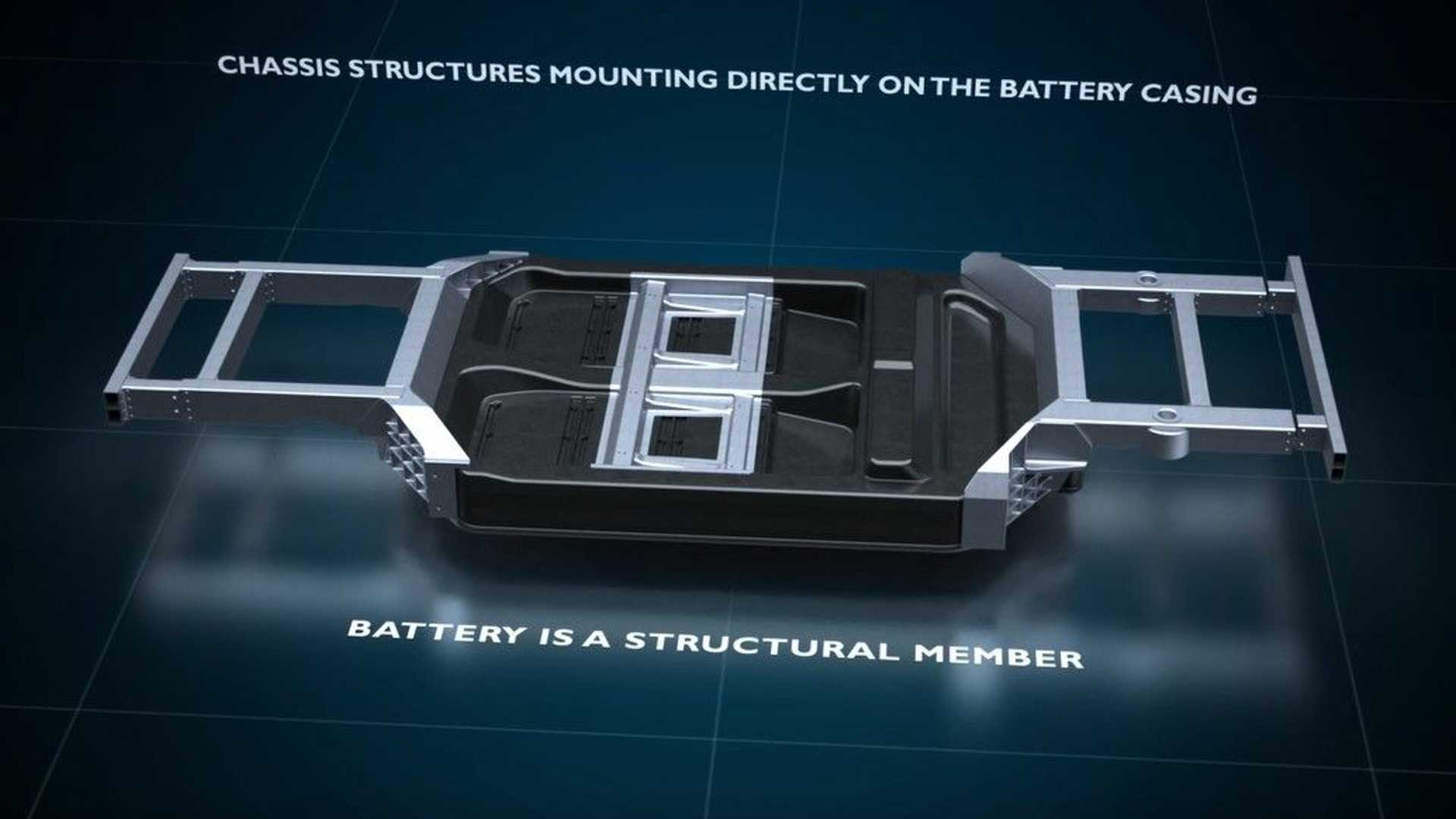

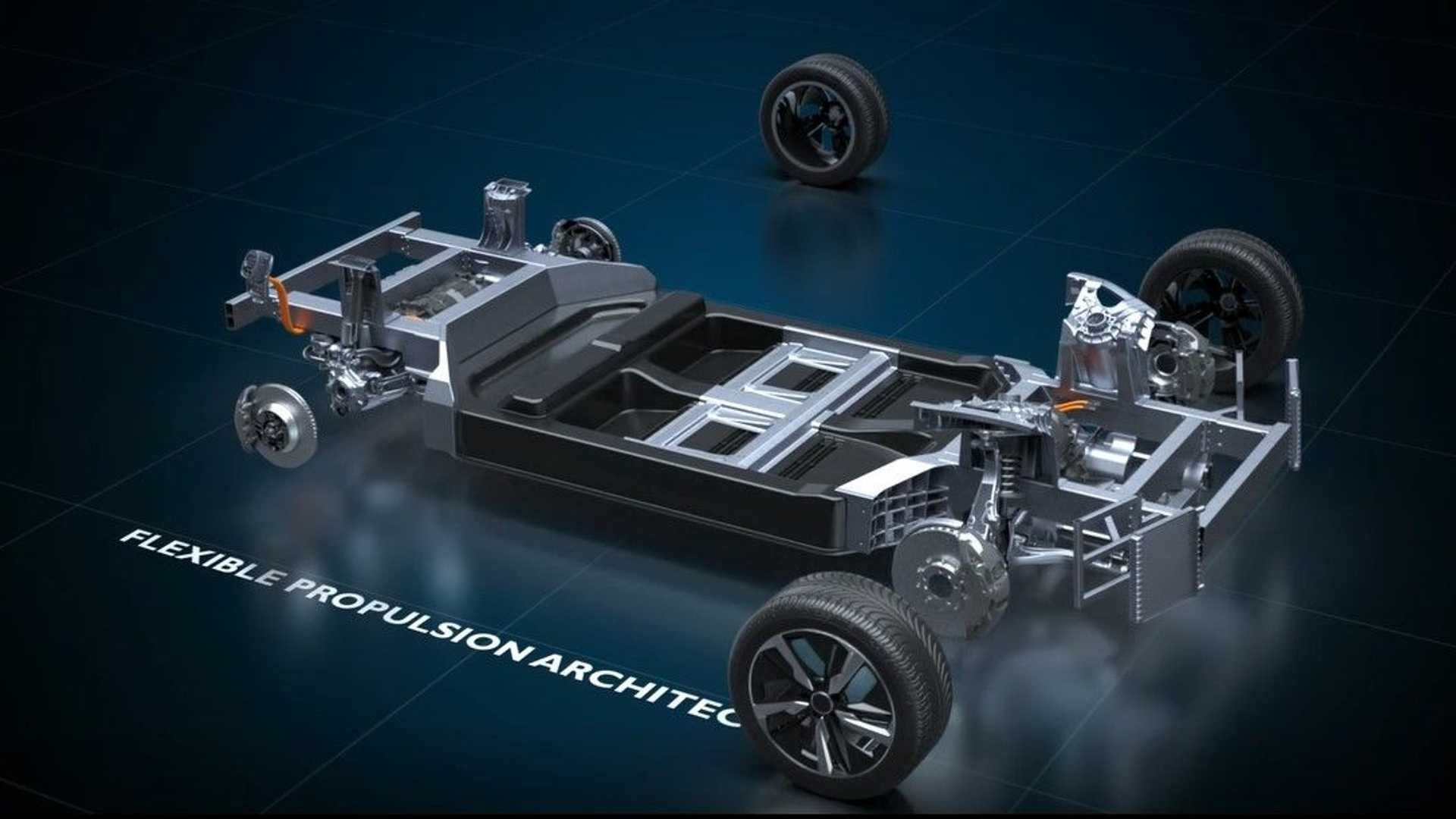

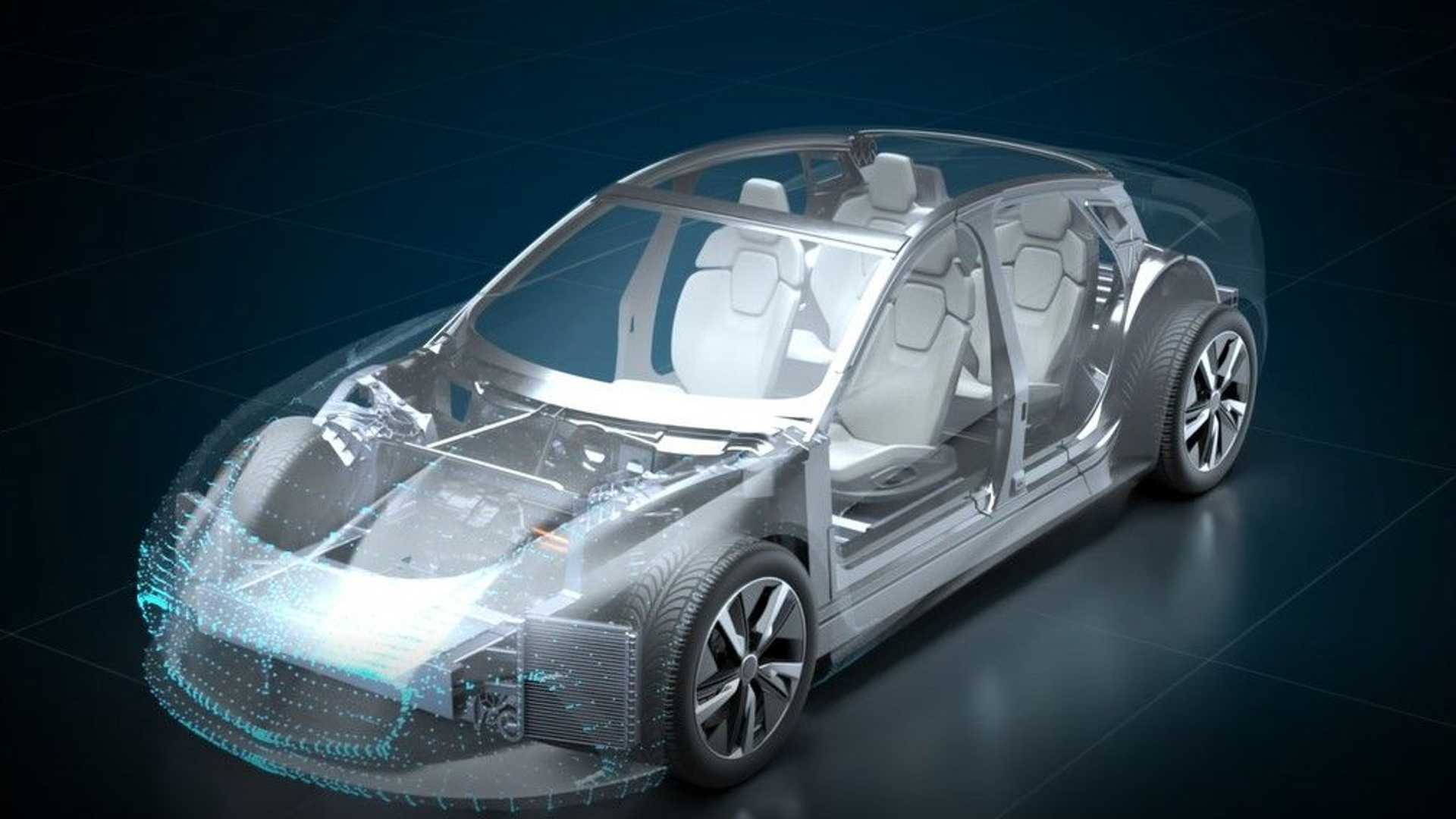

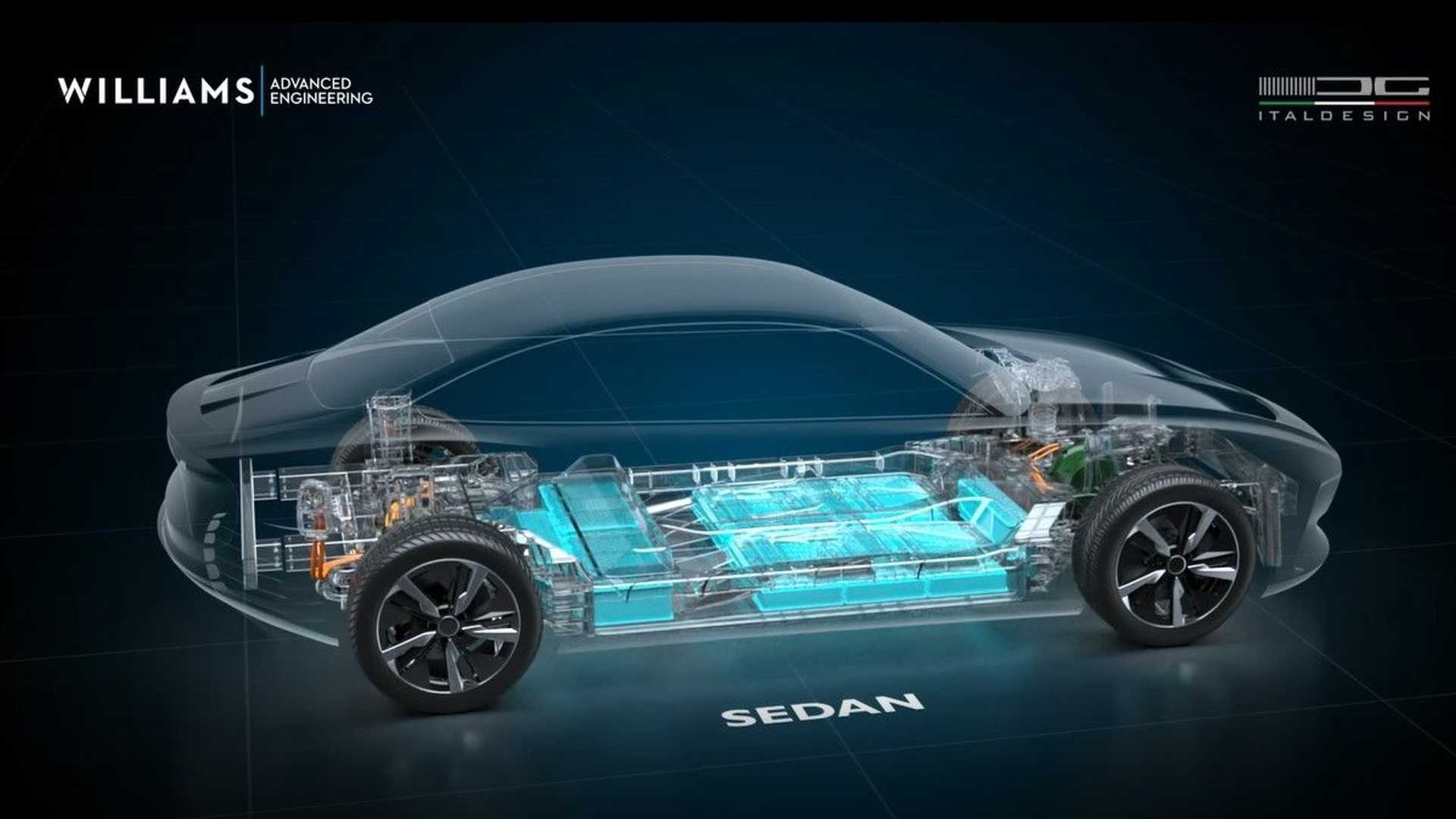

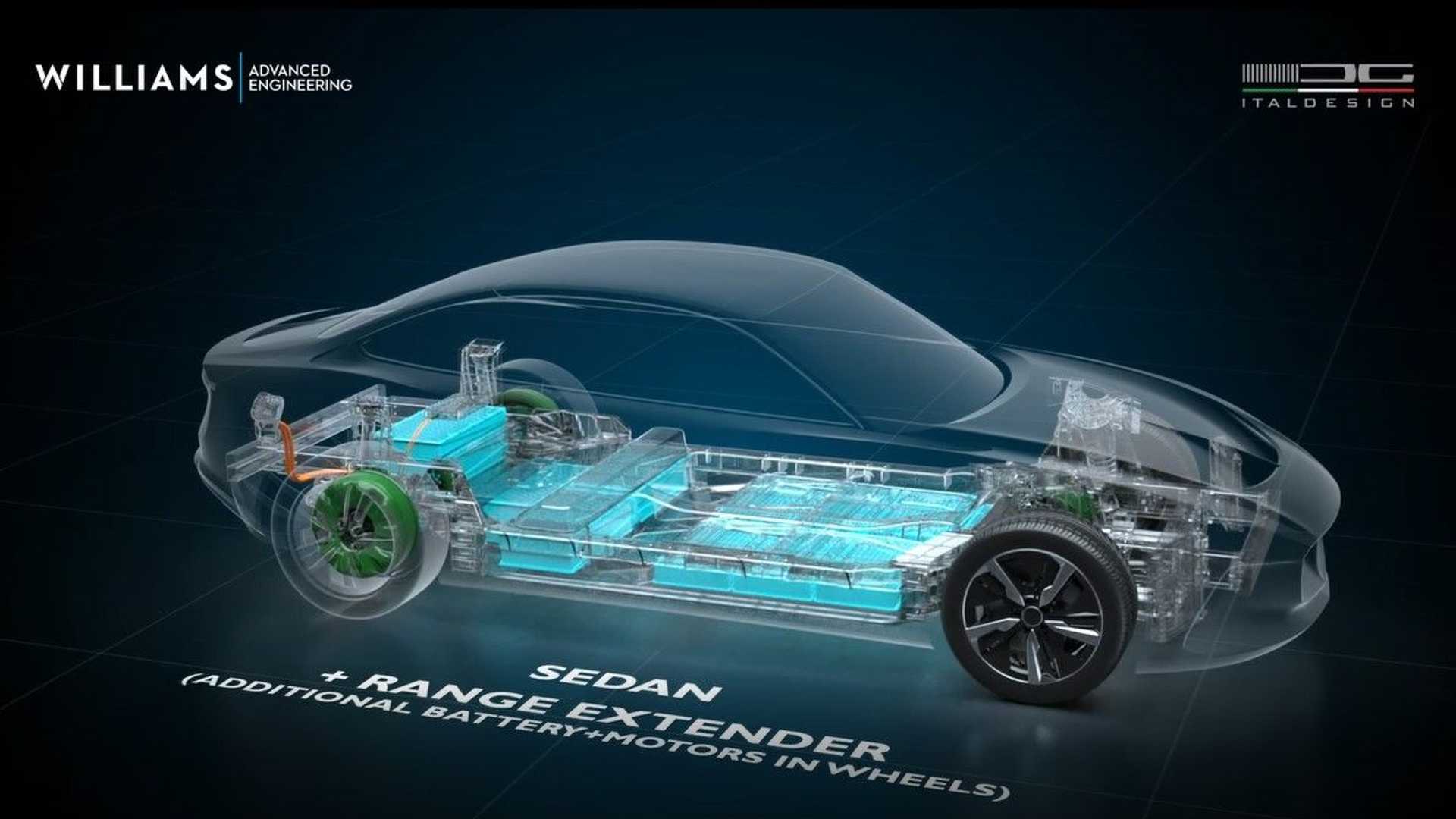

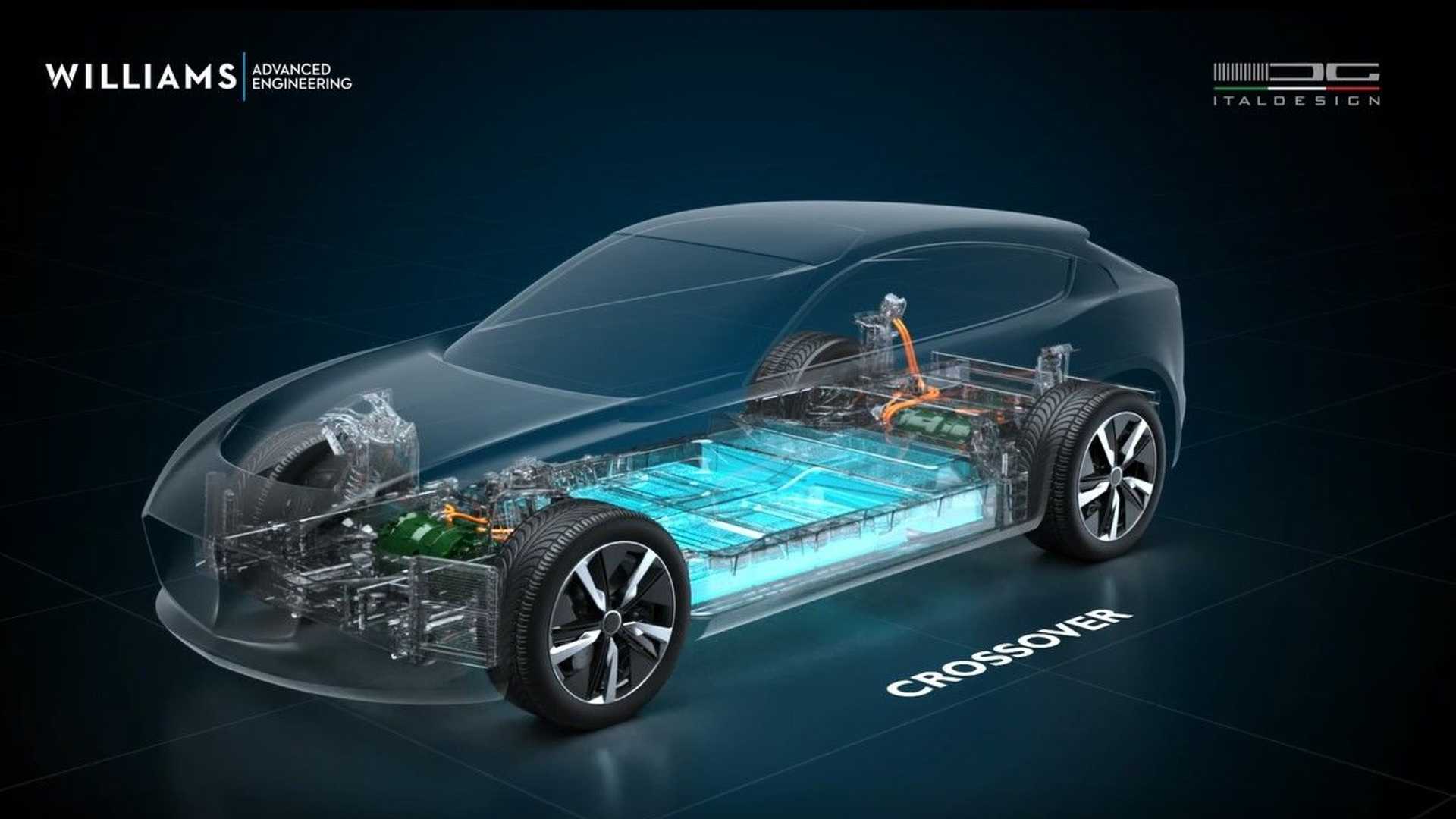

This architecture, dubbed EVX, sees the front and rear chassis structures mounted to the carbon composite case, meaning crash loads can be transferred via internal reinforcements to the integrated side sills. This results in improved torsional stiffness and reduces the reliance on the upper structure of the platform.

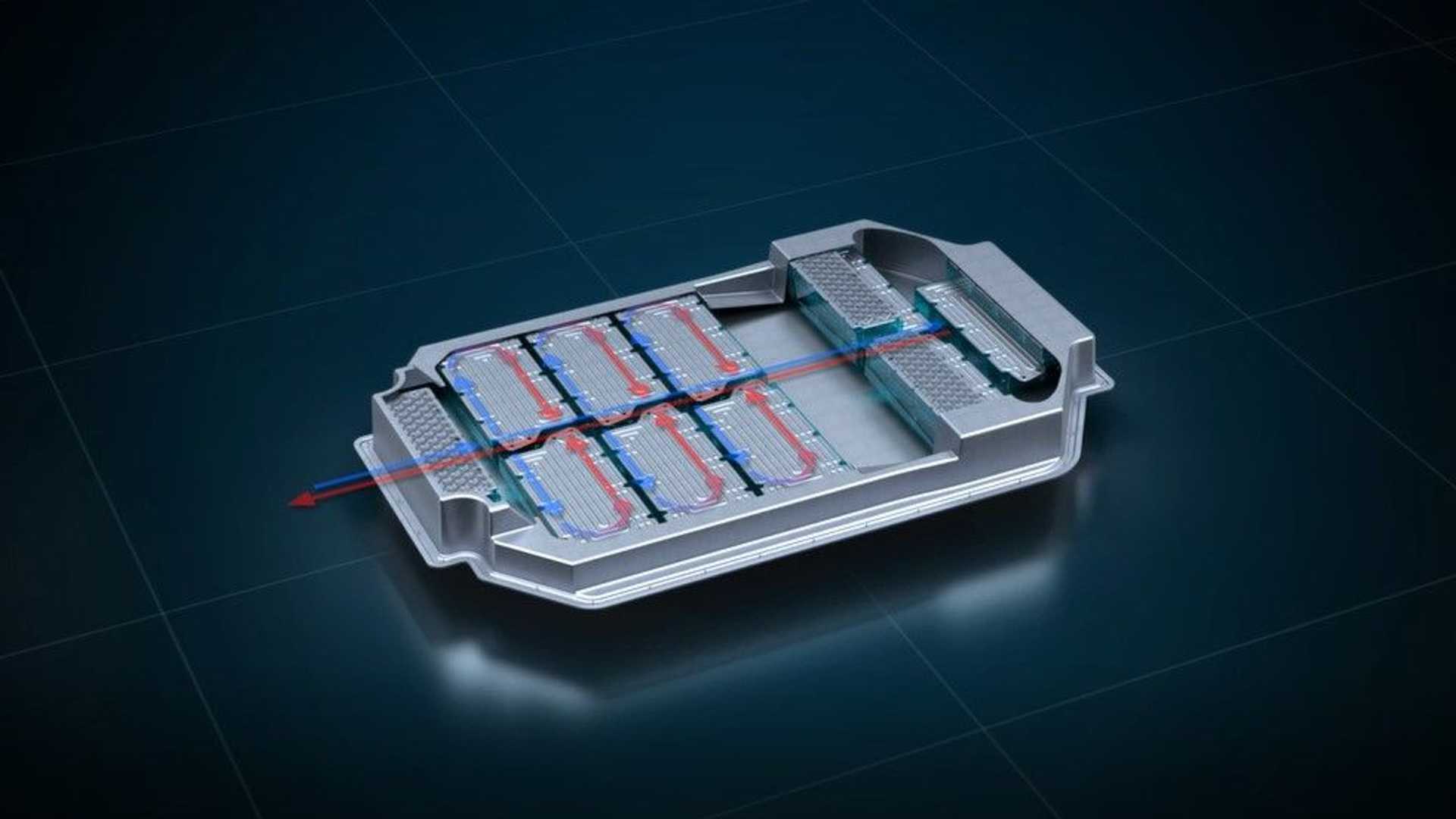

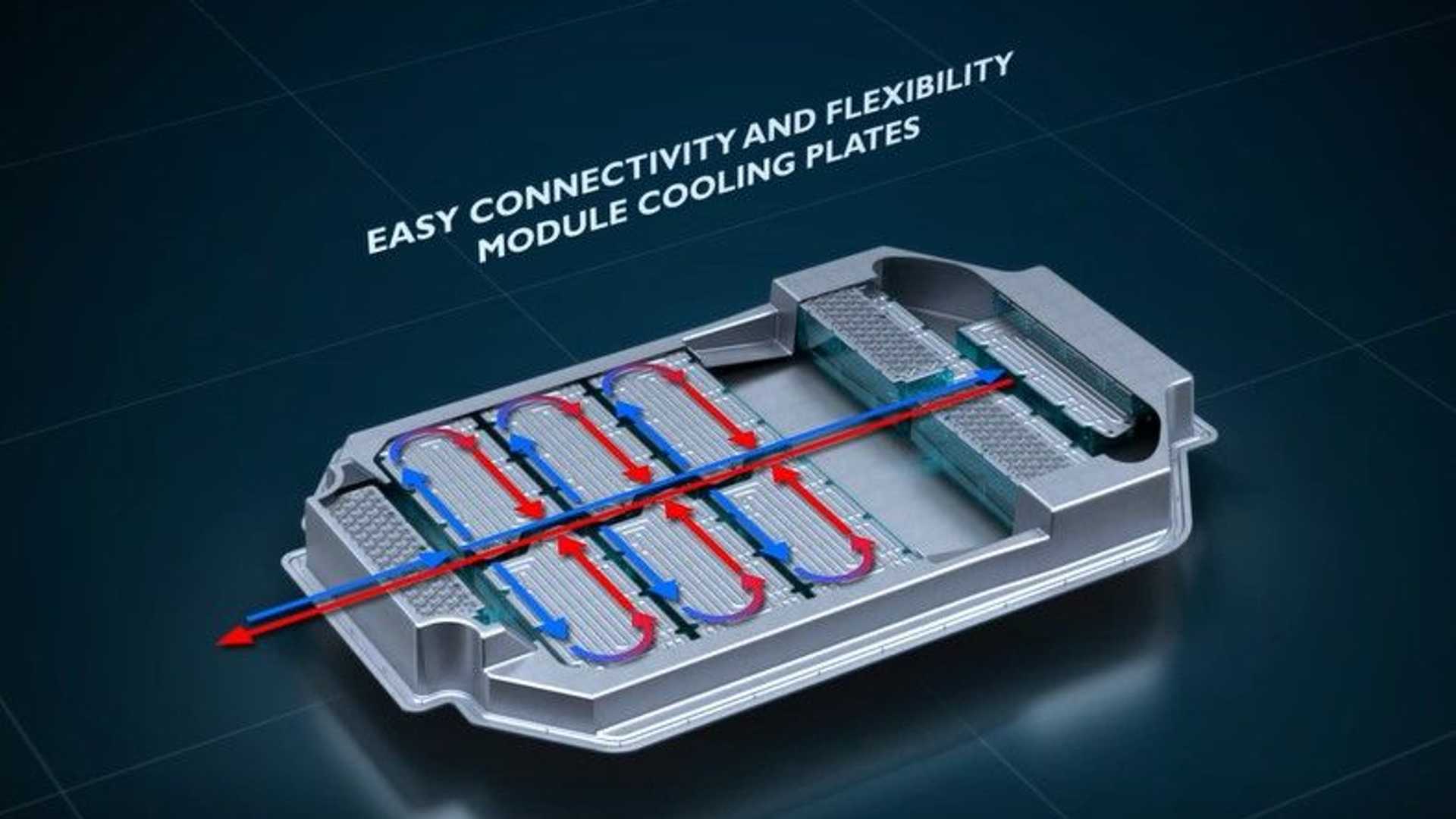

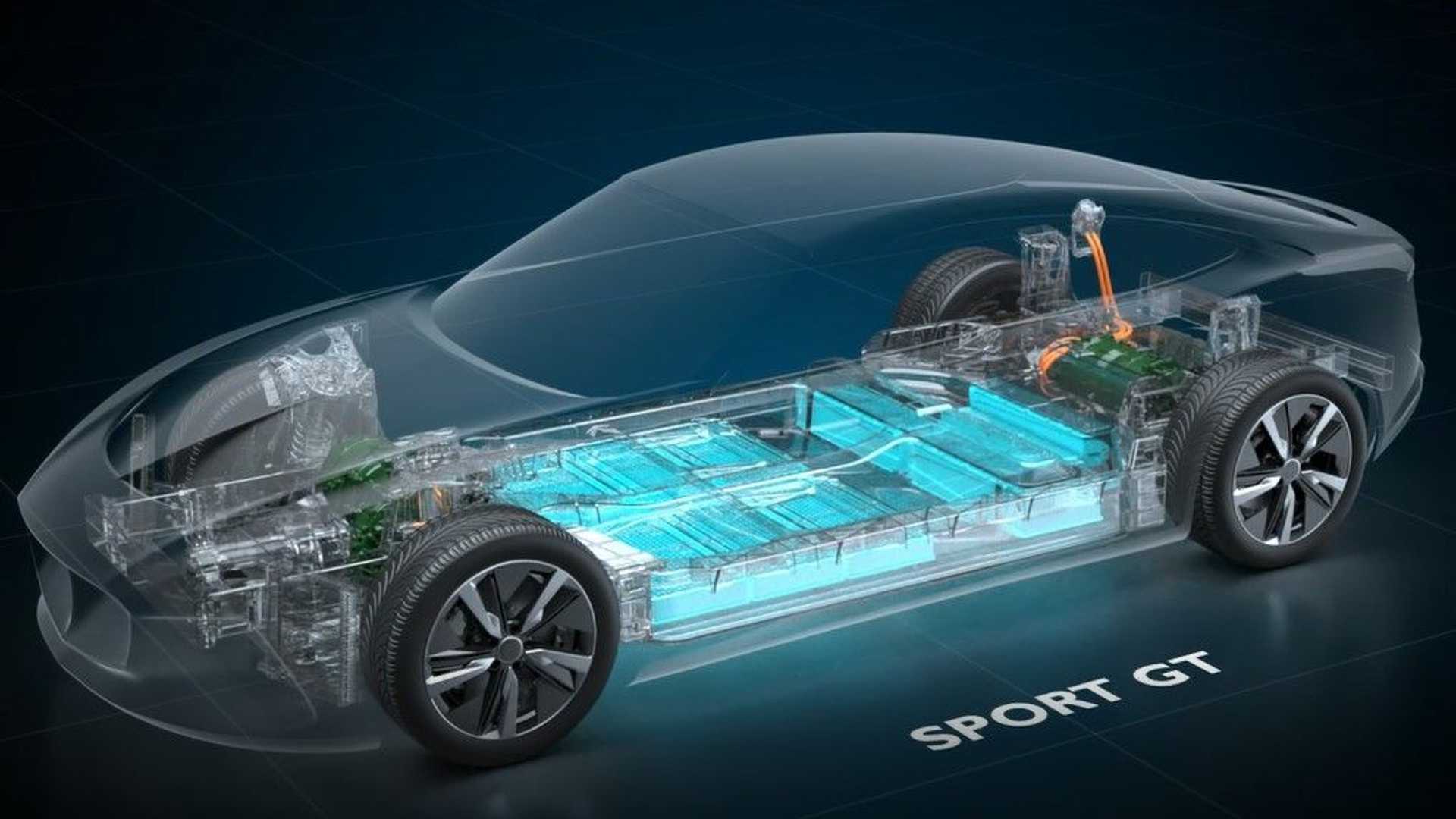

The molded composite structural battery was designed in-house by Williams Advanced Engineering and has the ability to provide 1000 kW (1,341 hp) of power and support capacities between 104 kWh and 120 kWh. If needed, the pack can be expanded up to 160 kWh for a potential 1,000 km (621-mile) range. The platform can accommodate wheelbases from 2,900 mm to 3,100 mm and also uses recycled composite materials in its construction.

Read Also: Lotus Terminates Evija Partnership With Williams Advanced Engineering, Prompting Legal Action

While Williams Advanced Engineering doesn’t currently produce any electric vehicles of its own, it has a wealth of experience in the sector having been the original supplier of batteries for the entire Formula E grid. The company also supplies battery systems to the ETCR and Extreme E championships.

“We are delighted to join forces with Italdesign on this exciting and timely joint collaboration,” Williams Advanced Engineering technical director Paul McNamara said. “Demand for high performance electric vehicles is continuing to show considerable growth but to date, there has not been a complete EV production solution. This unique relationship brings together state-of-the-art EV rolling chassis technology with one of the world’s leaders in vehicle body engineering.”

Italdesign and Williams want to provide the architecture to newcomers and established OEMs eager to produce high-performance GTs, crossovers, and sedans.