Mercedes has finally revealed the production version of the battery-electric EQC SUV, giving the world a first look before production begins at the Bremen plant in 2019.

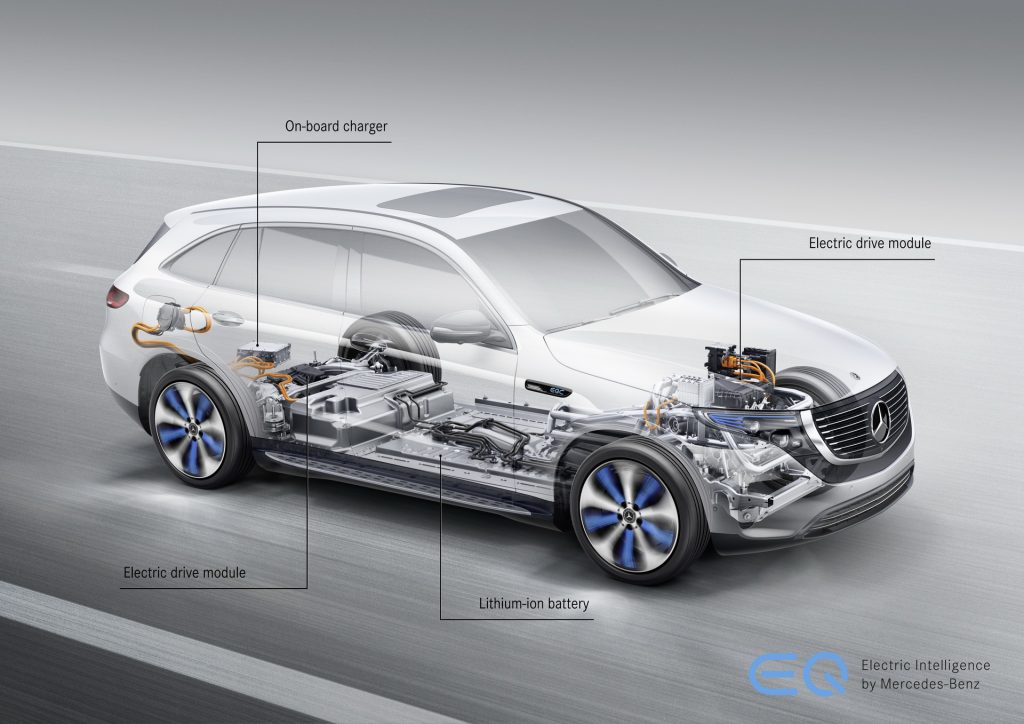

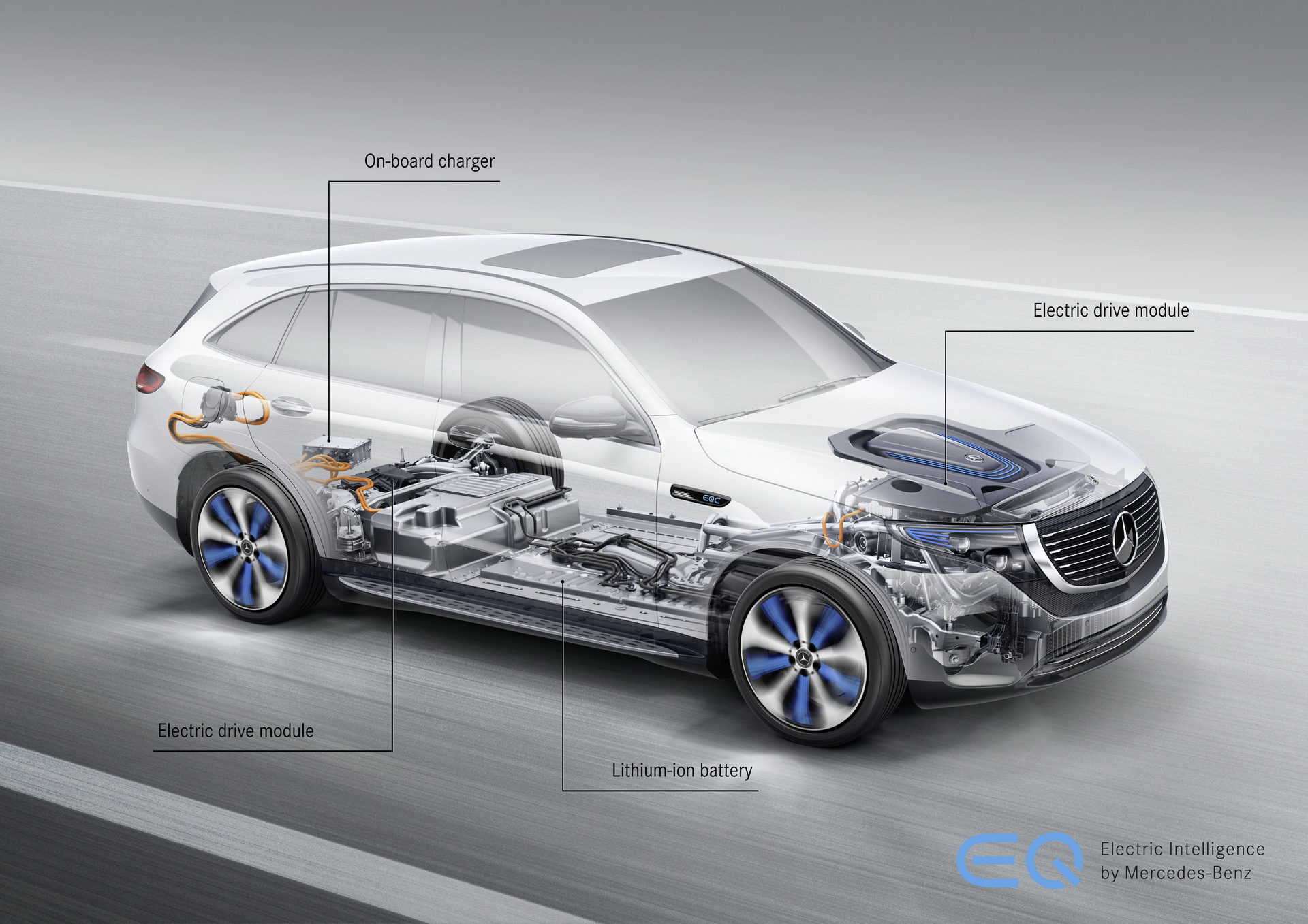

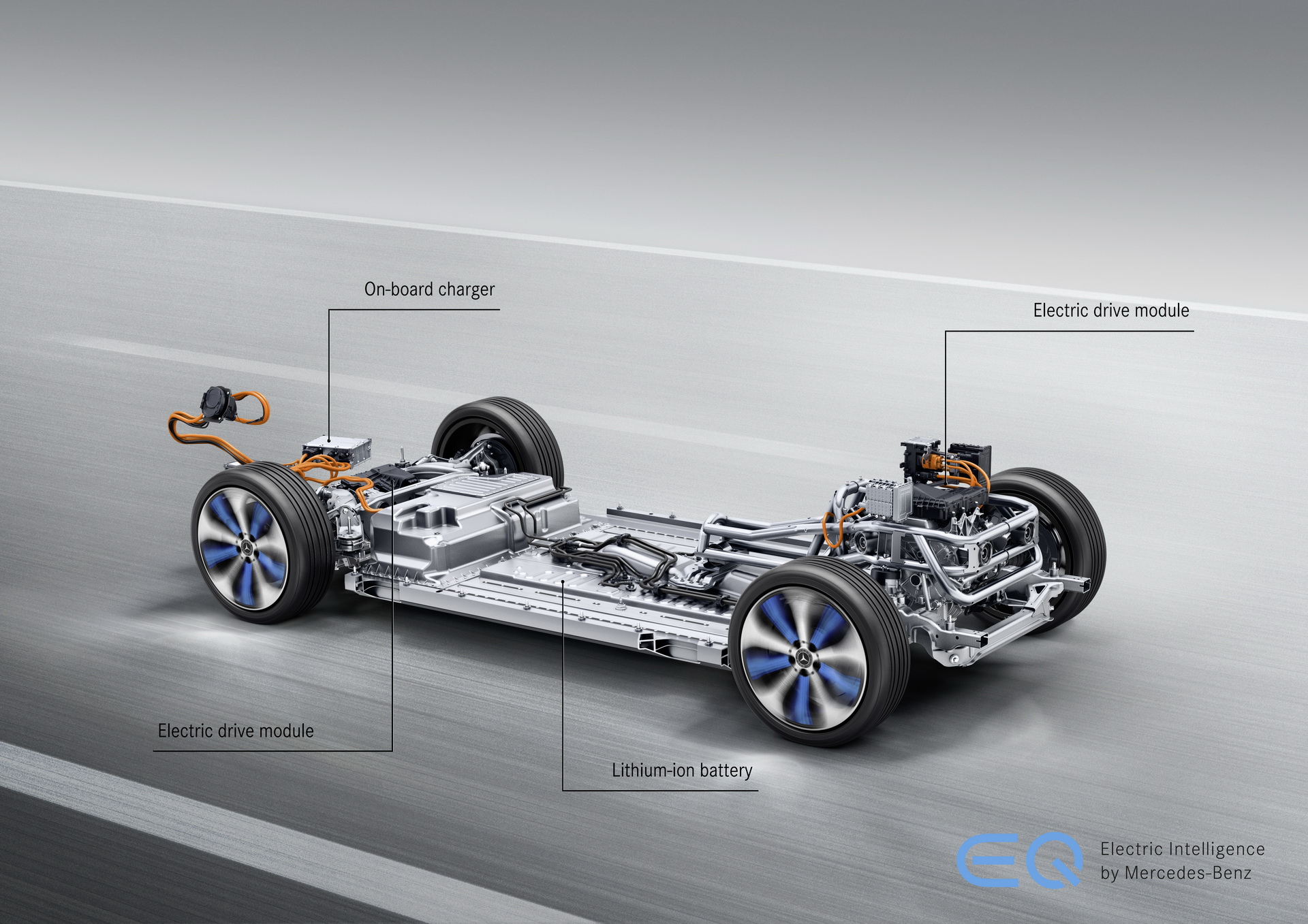

Τhe EQC’s pair of electric motors provide a combined 402hp (407PS) and 564lb-ft (765Nm) of torque, which is enough to send the electric crossover from 0 to 62mph (100km/h) in 5.1 seconds. A 80kWh battery pack mounted on the floor between the axles provides the EQC with the ability to travel for more than 279 miles (450km) on the NEDC cycle.

In theory, having an electric powertrain gives the opportunity to designers and engineers to explore new packaging ideas, since the electric motors require far less space and extra components when compared to an internal combustion powertrain. That’s why electric cars like Teslas offer a front trunk, or frunk as it’s called these days, in addition to the classic boot at the rear.

However, the EQC lacks such a feature, for the simple reason that under its bonnet, in the same space you would normally find an internal combustion engine, there’s the front drive module. The module houses the motor and the single-speed transmission together and sits in a cradle that’s isolated with rubber mounts, for noise-canceling reasons, at two points: where the module is connected to the subframe and where the subframe connects to the body.

You see, there’s the important issue of efficient series production; Mercedes deemed it would be much harder (and more expensive) to efficiently mass produce an electric vehicle that features a totally different layout than its current models.

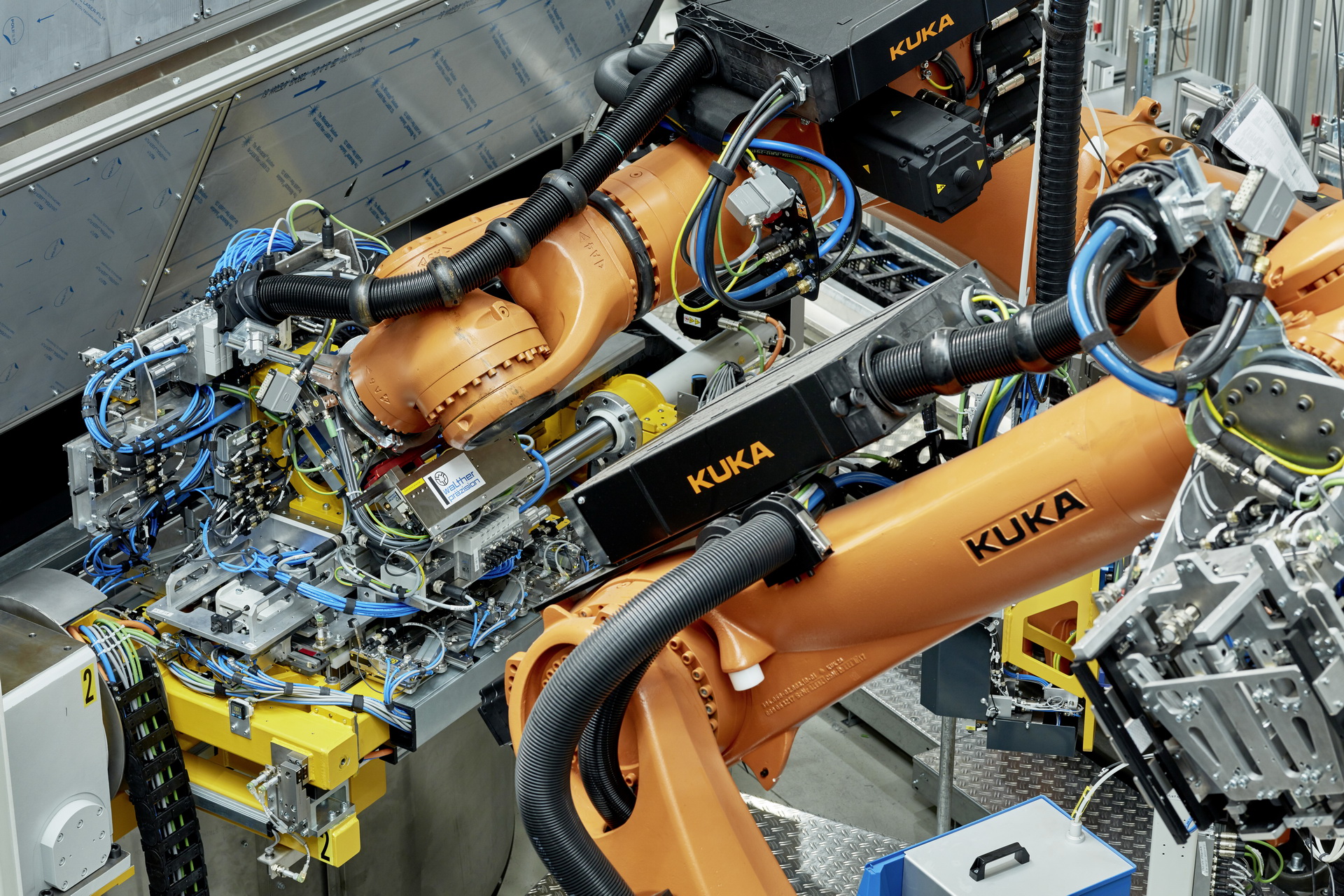

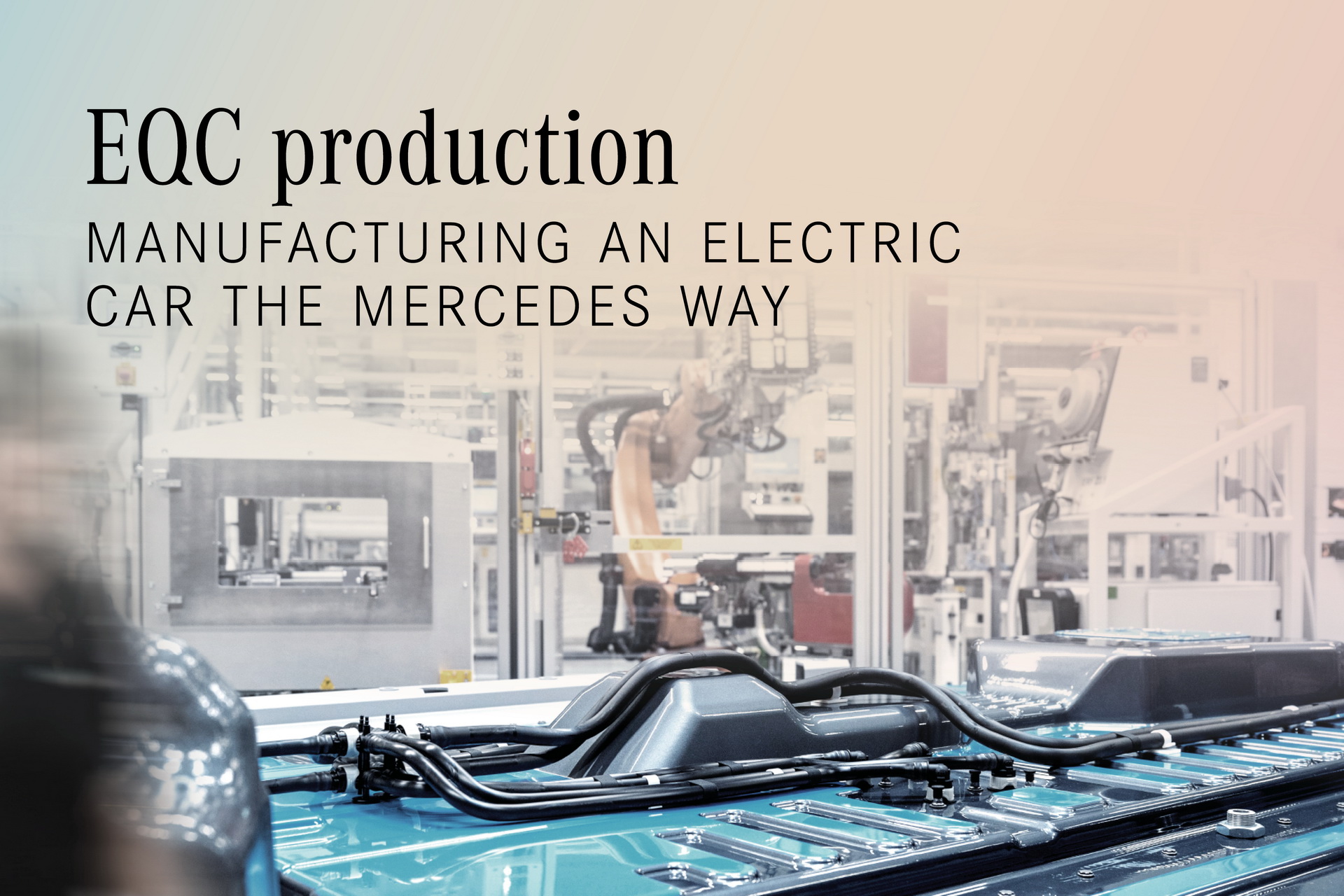

Instead, the German car maker opted to design and engineer its electric SUV in a way that it will allow them to integrate its production to its existing manufacturing standards. The front drive module and the rear axle assembly arrive at the factory already bolted to their subframes before being installed to the chassis, followed by mounting the battery pack to the floor. Don’t forget that the EQC will be produced on the same line with the C-Class, GLC and GLC Coupe at Bremen.

By integrating electric models into existing production lines, Mercedes gains a major advantage in the industry, making its plants instantly ready to adapt their production lines for all types of models, and that includes anything from combustion engines to hybrid and electric powertrains.

Sounds like the three-pointed star has solved the headache of EV mass production before it even starts building its first battery-electric vehicle.