- Hyundai will deploy Atlas robots in Georgia starting 2028.

- Robots will take over repetitive, risky factory floor tasks.

- Labor groups remain skeptical of long-term job security plans.

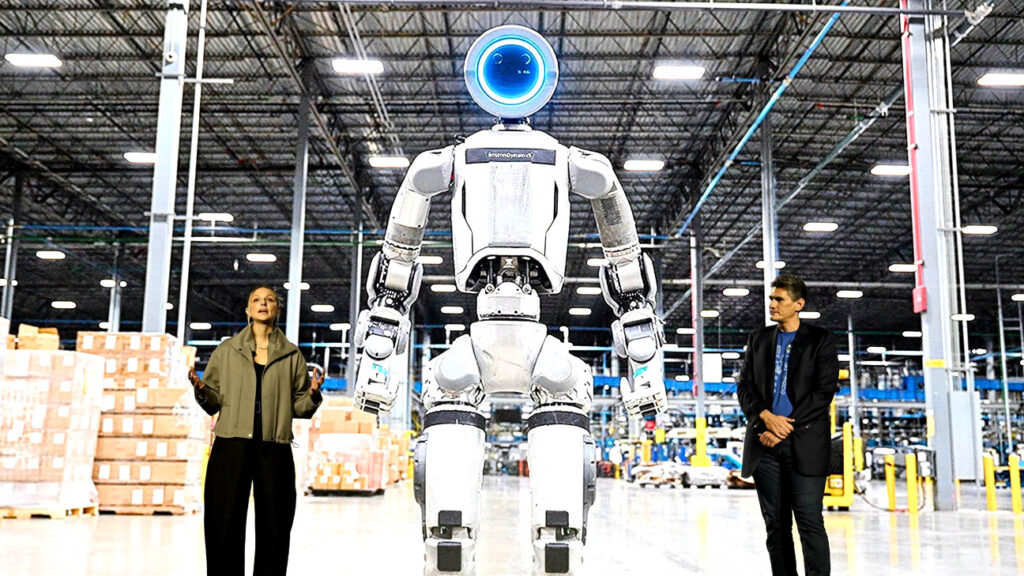

If your idea of a car factory is a big warehouse full of sparks, conveyor belts, and people in hard hats, you might want to update that mental image. Hyundai says that by 2028, some of the work at its Georgia plant will be done by a humanoid robot called Atlas. And yes, it walks around on two legs like something from a sci-fi movie.

Related: Hyundai’s Latest Robots May Be Eyeing Your Job

It’s an interesting development, especially in a country eager to revive factory jobs. What’s arriving instead, at least in part, is a workforce that’s mechanical, programmable, and tireless. Hyundai’s move responds to pressure for domestic manufacturing, but also highlights how the definition of “jobs” is shifting.

Atlas comes from Boston Dynamics, the slightly scary robotics company Hyundai bought in 2021. It’s not a gimmick robot designed to dance or fall over for YouTube clicks. This version is built for work. It’s got human-scale hands with tactile sensing, fully rotating joints, and the ability to lift up to 110 pounds (50 kg) without complaining about its back.

At first, Atlas won’t be bolting wheels onto cars or installing dashboards. It’ll start with parts sequencing, which basically means moving and organizing components before they’re installed. By 2030, Hyundai expects the robots to take on more complex assembly tasks, once they’ve proven they can do it safely and reliably.

It Will Do The Dirty Work

Hyundai’s pitching this as collaboration, not replacement. The robots take on the dull, dirty, and dangerous stuff, while humans focus on supervision, training, and higher level work.

The company also points out that someone has to build, program, maintain, and train the robots themselves, which creates new kinds of jobs even as old ones change.

That doesn’t mean everyone’s thrilled. Labor groups are watching closely, and some workers are understandably nervous about what a factory full of tireless machines means for long-term employment (and canteen banter, we’d have thought). Hyundai says it gets that concern and insists people will stay central to the process, even as automation increases.

What Is Physical AI Really For?

This all fits into Hyundai’s bigger push into what it calls physical AI, which is basically software brains inside hardware bodies that can sense, decide, and act in the real world. The same tech that helps a robot pick up a car part also underpins autonomous driving and smart factories.

So yes, your next Hyundai might have been helped along the line by a robot that looks a bit like a person. It’s weird, and a little unsettling, but – given the potential efficiencies for automakers – probably inevitable, just like the industry-wide switch to Henry Ford’s production line system a century ago.

Unsurprisingly, Hyundai isn’t the only brand jumping on this idea. Tesla is developing its own robots and this year Mercedes began testing its own humanoids at its Berlin plant.