BMW (holding a 49% stake) and SGL (holding 51%) have joined forces to create SGL Automotive Carbon Fiber LLC, which will be located in Moses Lake, Washington. The joint venture will build a $100 million “state-of-the-art carbon fiber manufacturing plant” and help create 80 local jobs.

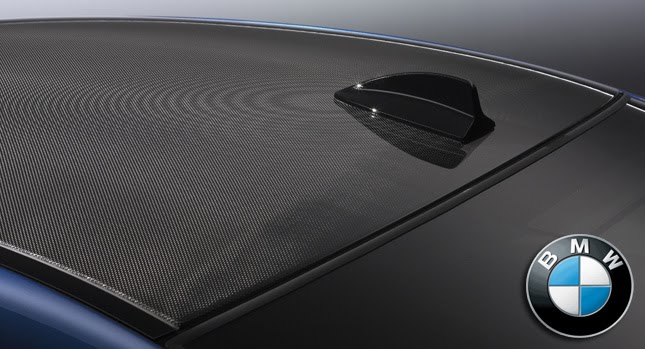

According to SGL ACF LLC, the end result will be carbon fiber reinforced plastics (CFRP) “used for BMW Group’s upcoming Megacity Vehicle.” They’re referring to what will be the end result of BMW’s Project i, a mode of transport “designed for fully electric, zero-emission driving.”

Why build in Moses Lake? Mainly, energy costs in Washington state are highly competitive and there’s access to renewable hydropower [re: it’s green as grass]. Other factors included “favorable infrastructure conditions, existing utilities, a skilled labor force and ease of working with the local government.”

Robert Koehler, SGL Group’s CEO, talked about the project: “It will be the world’s most cost efficient carbon fiber plant using state-of-the-art technologies. This significant investment further underlines our commitment to the U.S., where we already operate carbon fiber and composite materials plants…We will ensure that carbon fibers play a revolutionary role in lightweight automotive construction.”

Friedrich Eichiner of BMW added, “With using CFRP components in our Megacity Vehicle, we take sustainable mobility a step further. By combining the know-how of SGL Group and our expertise in manufacturing CFRP components, we will be able to produce carbon fiber enhanced components in large volumes at competitive costs for the first time. This is particularly relevant for electric-powered vehicles such as the Megacity Vehicle.”

With recent BMW trademarks including everything from an i1 and i2 to E8s and E9s, there’s no time like the present to start speculating on what the first majority-CFRP BMW product will be. Being old-school, here’s hoping the Isetta makes a comeback.

By Phil Alex