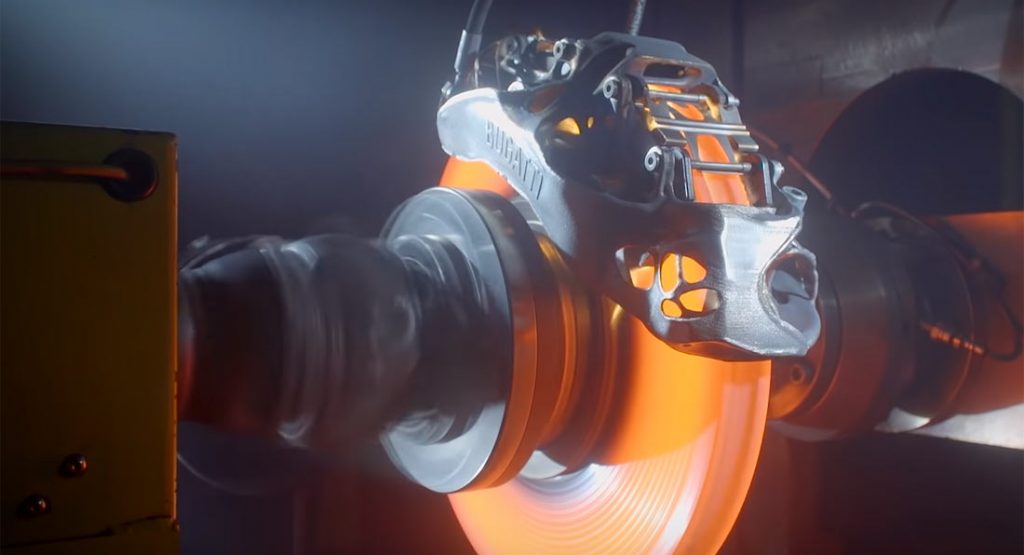

Bugatti has produced the largest 3D-printed component ever manufactured from titanium: a new brake caliper for the Chiron.

The French automaker has been developing the new caliper throughout 2018 and parent company Volkswagen has just dropped a video showing it being tested to its limits.

As the Chiron can comfortably exceed 250 mph (402 km/h), every component of the vehicle has to be vigorously tested at extremes far beyond what normal production cars have to deal with. During recent testing of the caliper, Bugatti fitted it to a machine to mimic the speed and forces of a Chiron braking from 233 mph (375 km/h). While the brake disc glows orange as it exceeds 1000 degrees Celsius, the titanium brake caliper copes without any issus.

Bugatti’s new caliper features eight pistons, measures 16-inches in diameter, weighs just 6.4 pounds (2.9 kg), making it 40 per cent lighter than the ones currently used by the Chiron, and can withstands 275 lbs (125 kg) of force per square millimeter.

Responsible for its creation are four 400-watt lasers which, over 45 hours, deposit 2213 layers of titanium powder. Bugatti hasn’t said when the Chiron will receive the new brake calipers and if they will be standard or an optional extra.

https://youtu.be/hPkY8nBWxoU