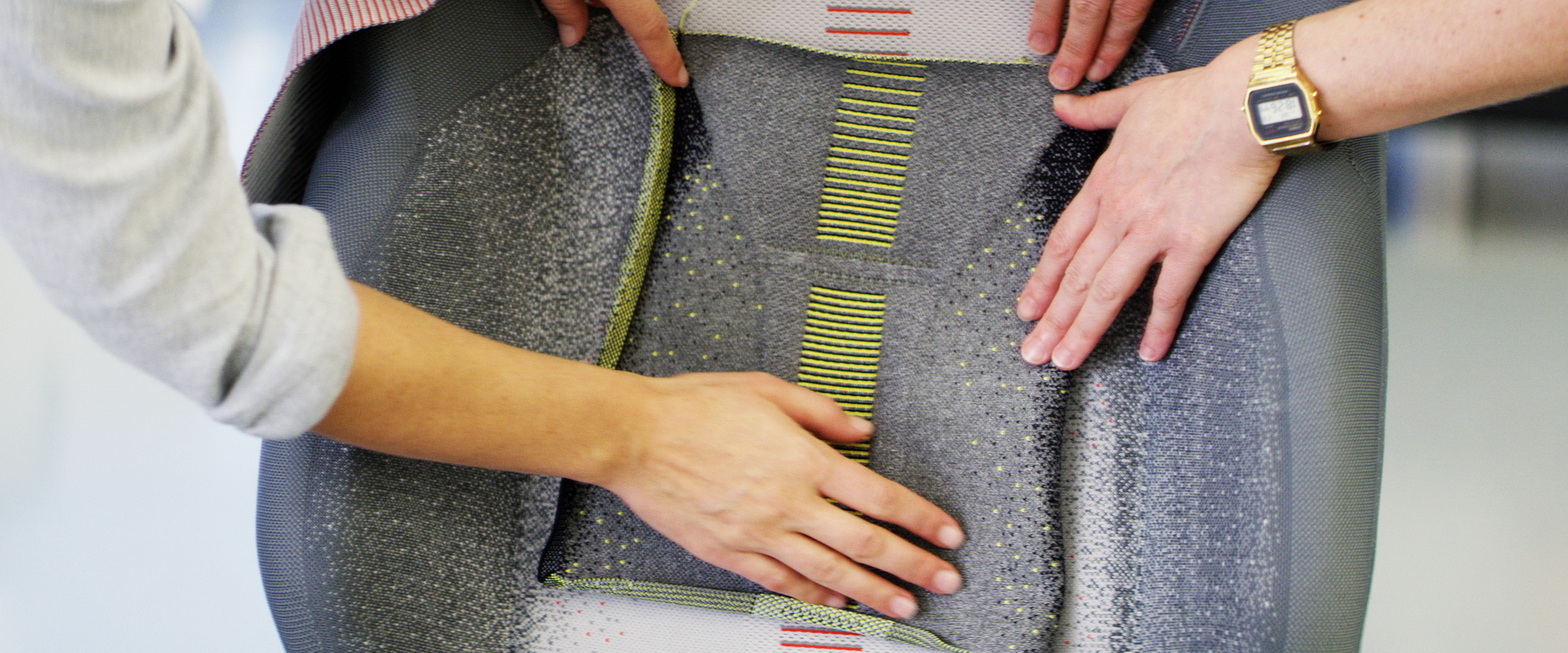

Ford is introducing a new way of producing better car seat upholstery with the help of 3D knitting, a cutting edge technique that allows seamless seat covers and infinite personalization.

The production technique is usually found on running shoes, clothing and furniture, and opens new possibilities for automotive applications. Ford wants to let customers to design their own seats, letting them add bespoke touches like pockets or padding, as well as use more breathable materials for the summer.

3D knitting also enables them to use textiles capable of built-in connectivity in car seats, including controls for the doors and windows, integrated heating and sensors to monitor the driver’s health, as well as wireless phone charging.

Related: Hyundai Working On Active Road Noise Control Technology

“3D knitting offers intriguing possibilities that push the boundaries of design and make journeys more comfortable and convenient for the driver and passengers,” said Anais Castinel, interior designer, Ford of Europe.

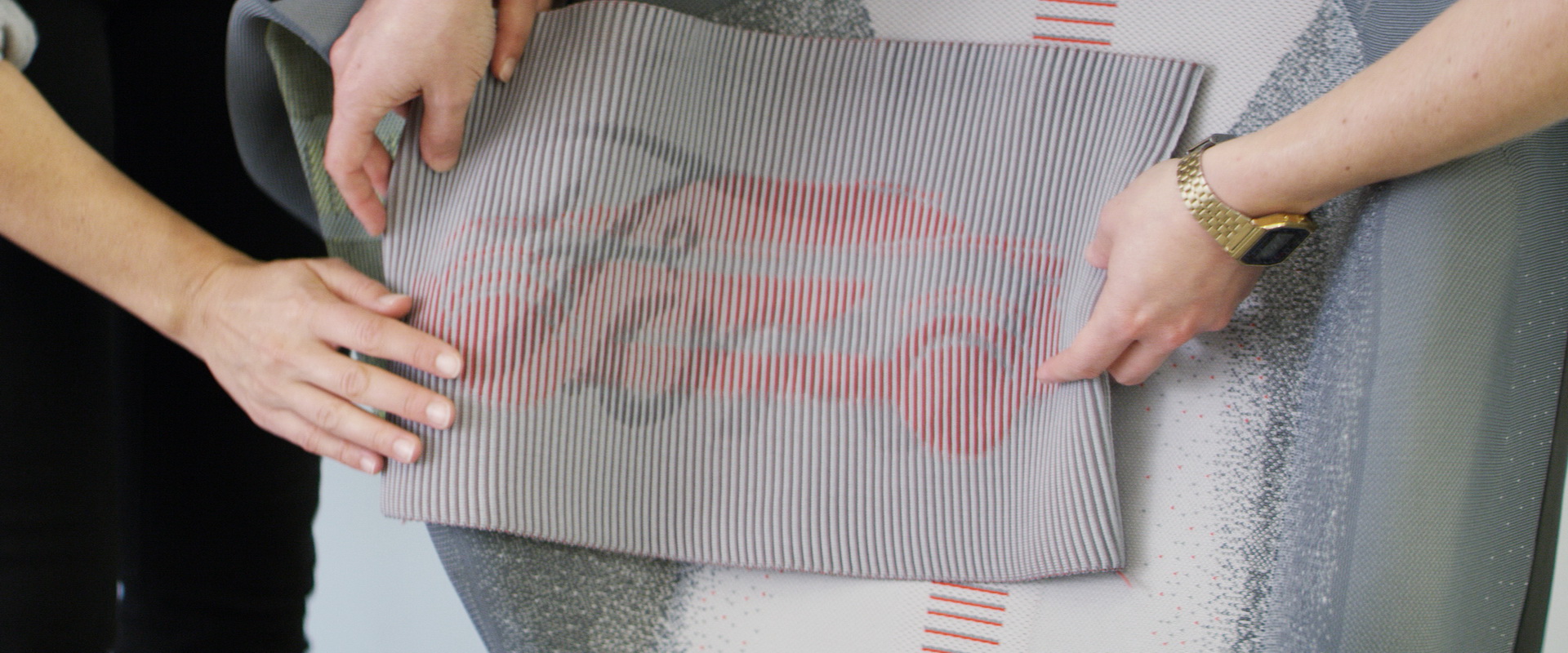

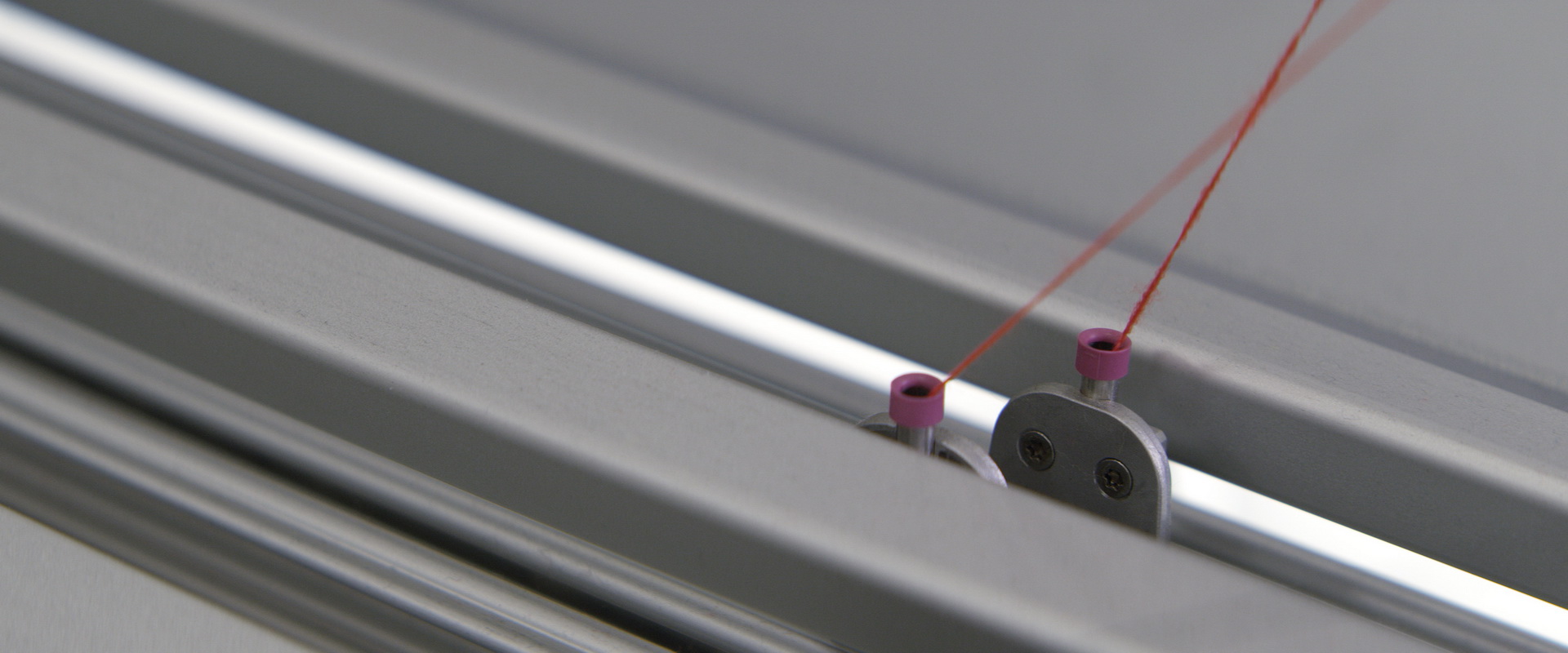

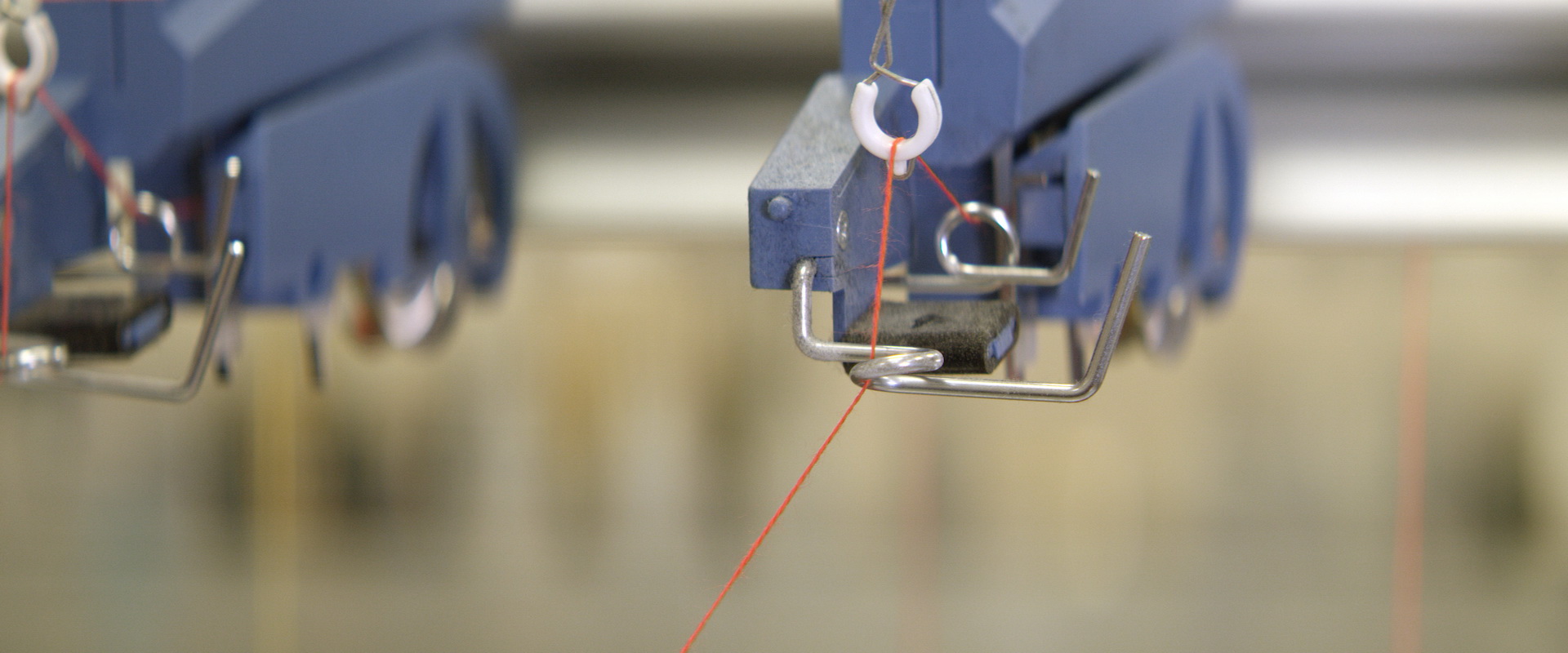

The process of 3D knitting also cuts down production steps and creates less waste as it removes the need to cut and sew together different fabrics and pieces. It creates covers with no stitching, and can use different yarns, such as wool, silk, carbon fiber and even recycled materials. Moreover, this technology results to higher precision and quality than a traditional cover, reducing wrinkles and other imperfections.

Any interior part can feature a 3D-knitted material, including the dashboard and door cards. Customers could have the option of different seat covers on the front and rear seats, like a set with a design for children or a seat cover made especially for pets, while individual colors and graphics can be offered to those wishing for a more bespoke interior.