Volvo has become the first carmaker to use blockchain technology in order to trace the cobalt used in their batteries. According to them, the traceability of raw materials used to produce lithium ion batteries is a big challenge when it comes to sustainability.

The use of blockchain technology is said to significantly boost transparency of the raw material supply chain, so that information about the material’s origin cannot be changed undetected.

The Swedish company has reached an agreement with both of its global battery suppliers in CATL of China and LG Chem of South Korea, as well as leading global blockchain technology firms – the goal is to implement traceability of cobalt starting this year.

Also read: Porsche Looking Into Blockchain Tech For Future Vehicles

“We have always been committed to an ethical supply chain for our raw materials,” said Volvo exec Martina Buchhauser. “With blockchain technology we can take the next step towards ensuring full traceability of our supply chain and minimising any related risks, in close collaboration with our suppliers.”

For those who don’t know, a blockchain is a digital ledger that contains a list of records liked via cryptography. In terms of supply chains, this system creates transaction records which cannot be altered, so when it comes to the cobalt’s origin, attributes such as weight and size, plus chain of custody can be verified as per OECD supply chain guidelines.

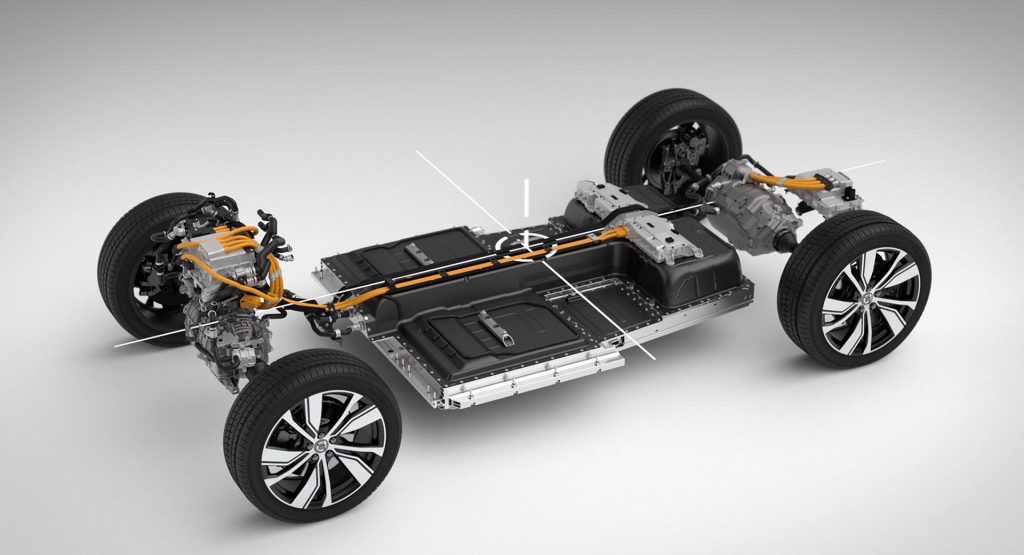

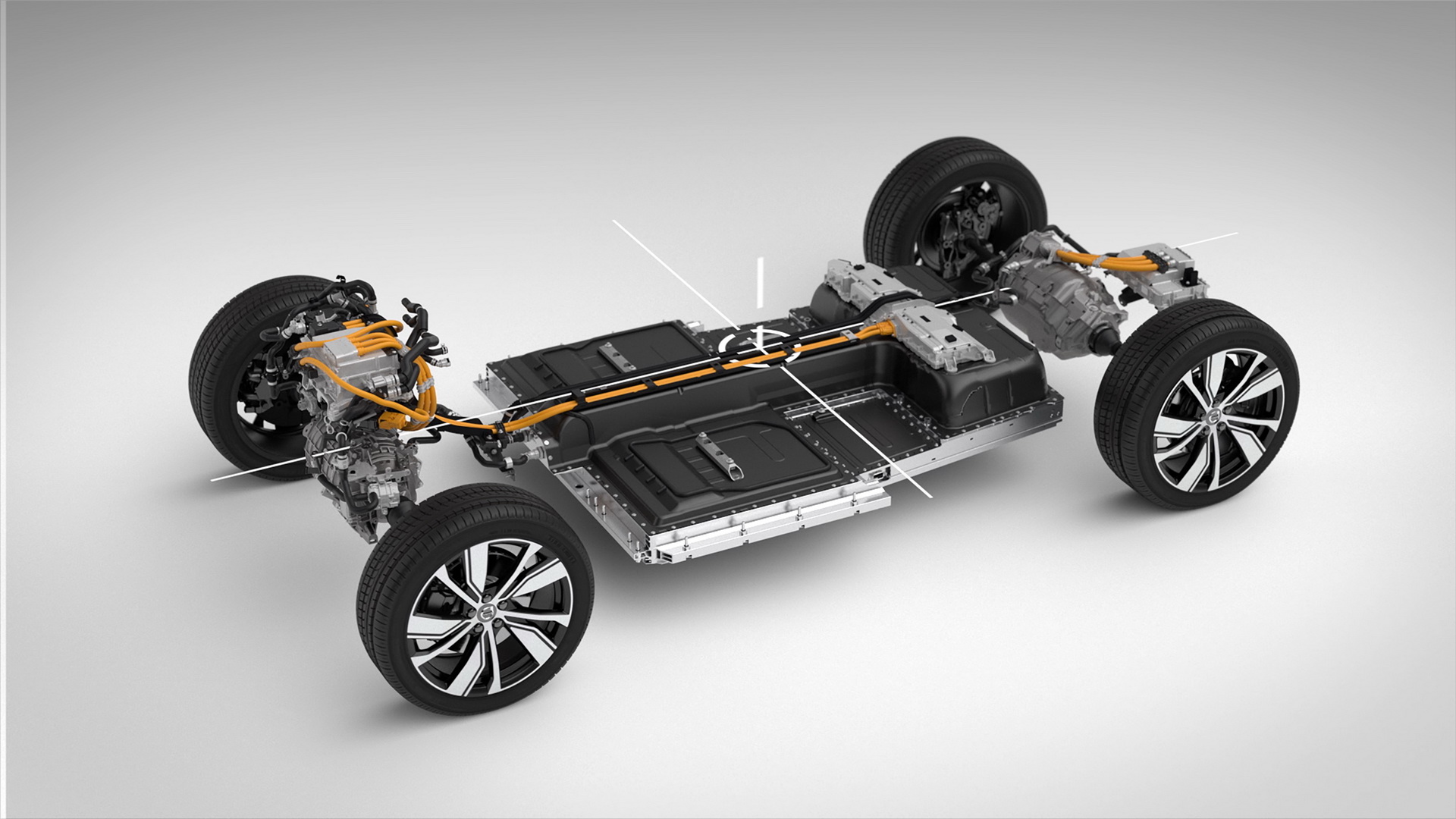

Volvo’s deal with CATL and LG Chem covers the supply of batteries over the coming decade for next-gen Volvo and Polestar models, including the recently revealed XC40 Recharge.