Nissan isn’t giving up on the internal combustion engine just yet and has confirmed it can create an engine with a thermal efficiency of 50 per cent.

A typical production engine has a thermal efficiency of around 40 per cent, meaning 40 per cent of the energy created when its fuel is burned is turned into motion. In 2017, the Mercedes-AMG Formula 1 team said its race engine had reached the seemingly impossible 50 per cent thermal efficiency mark and Nissan says that it now has the technology and know-how to do so as well, effectively improving fuel consumption by 25 per cent.

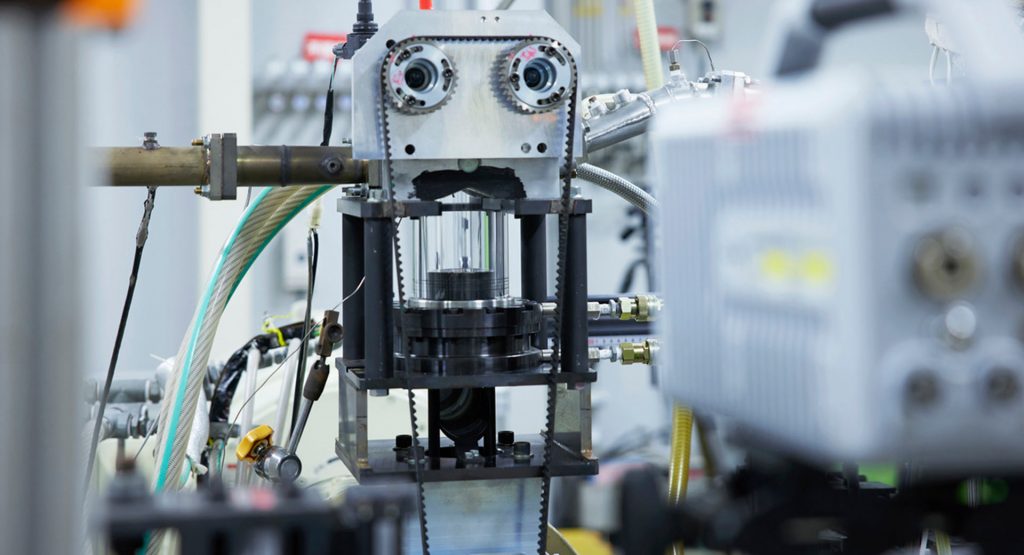

This isn’t a regular engine, however. Instead, the engine developed by Nissan is used to charge a battery that powers the wheels courtesy of some electric motors. To hit the 50 per cent mark, Nissan’s engine can run a lean mixture at a higher compression ratio. As Reuters notes, it has done this by forcing more fuel and air into the cylinder and igniting it with a stronger spark.

Watch Also: Latest Mercedes F1 Engine Hits 50% Thermal Efficiency

In testing, the system hit 46 per cent thermal efficiency while the remaining 4 per cent has been gained using unspecified “waste heat recovery technologies.” This new engine forms part of what Nissan dubs its e-Power drivetrain and while it is not yet ready for production, it is coming soon.

“Nissan’s latest approach to engine development has raised the bar to world-leading levels, accelerating past the current auto industry average range of 40% thermal efficiency, making it possible to even further reduce vehicle CO2 emissions,” the company said in a statement.

“It took 50 years to increase thermal efficiency (of conventional engines) from 30% to 40%,” added senior vice president of the powertrain and EV engineering division at Nissan, Toshihiro Hirai. “But with e-POWER, we can increase it to 50% in several years. That has been the target for the engineering community.”