BMW has more than doubled the production capacity of high-voltage batteries at its plant in Spartanburg, South Carolina.

The plant’s battery facility has begun building the new fourth-generation batteries that will be used in the plug-in hybrid versions of the new BMW X5 and the BMW X3 — both also produced in Spartanburg.

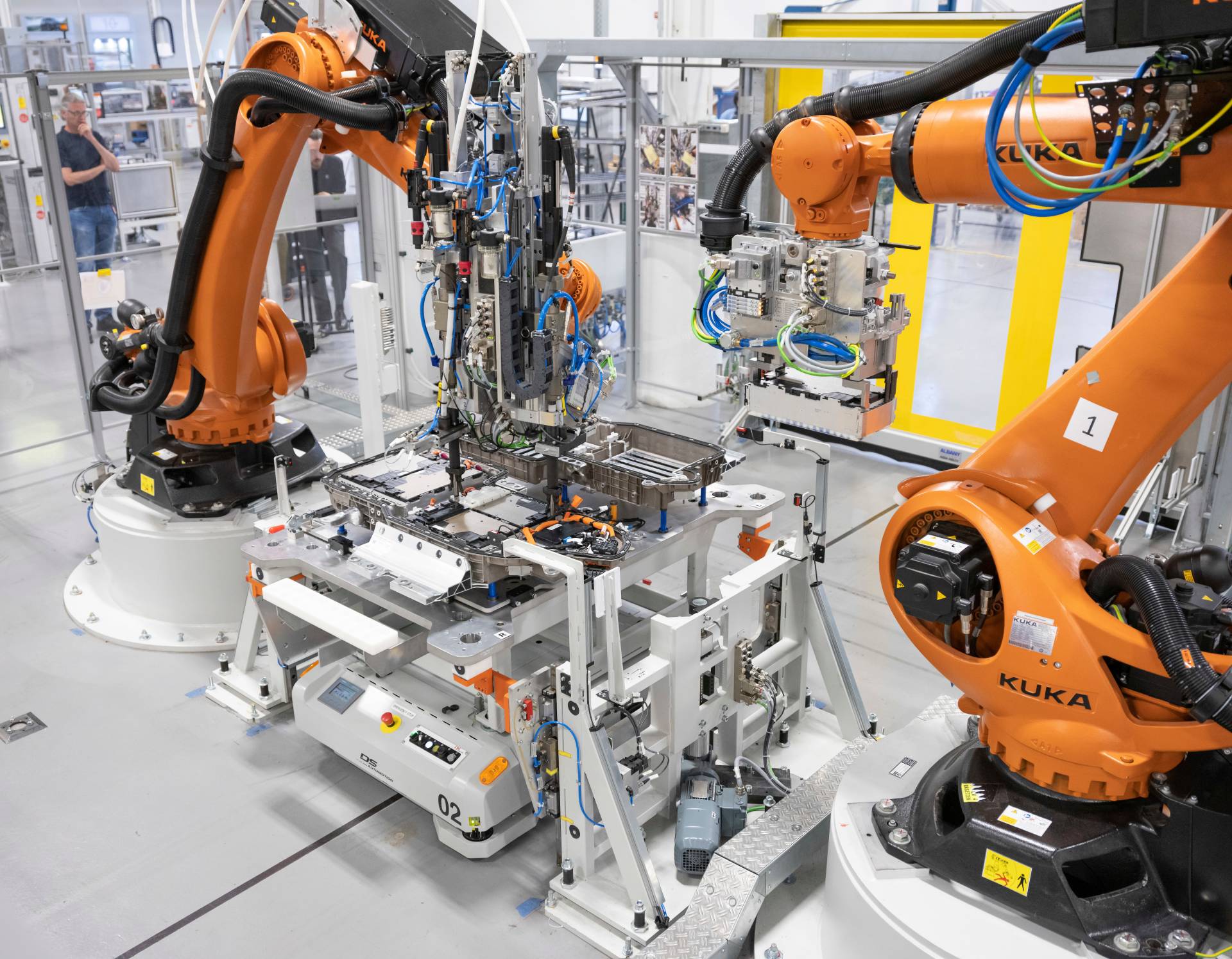

“We have invested around ten million US dollars in a new battery assembly line and expanded the area to more than 8,000 square meters. This means we could double the number of batteries produced if needed to meet market demand,” said Michael Nikolaides, Senior Vice President Engines and Electrified Drivetrains, BMW Group.

BMW will be able to build different types of fourth-generation batteries on the new assembly line to meet growing demand for electrified vehicles. More than 120 people will be employed in battery production at Spartanburg by the end of this year.

The plant has produced a total of more than 45,000 batteries since 2015, most of them for the previous generation BMW X5 xDrive40e plug-in hybrid. Its successor, the 2019 BMW X5 xDrive45e iPerformance, will enter production in August this year, followed by the smaller BMW X3 xDrive30e in December. As the name suggests, the latter model will use the same powertrain as the BMW 330e plug-in hybrid.

“The BMW X5 and BMW X3 are currently among the top-selling BMW models in the US. We expect their plug-in hybrid variants to be just as popular with customers,” said Knudt Flor, President and CEO, BMW Manufacturing.

Since the start of 2019, the BMW Group has invested a further $10 million in production of plug-in hybrid models, with an additional 225 vehicle assembly workers being trained in the production of electrified models.