BMW is going to spend roughly €1 billion ($1.05 billion) between now and 2030 in transforming its factory in Steyr, Austria into a site that leads the production and development of its next-generation electric powertrains.

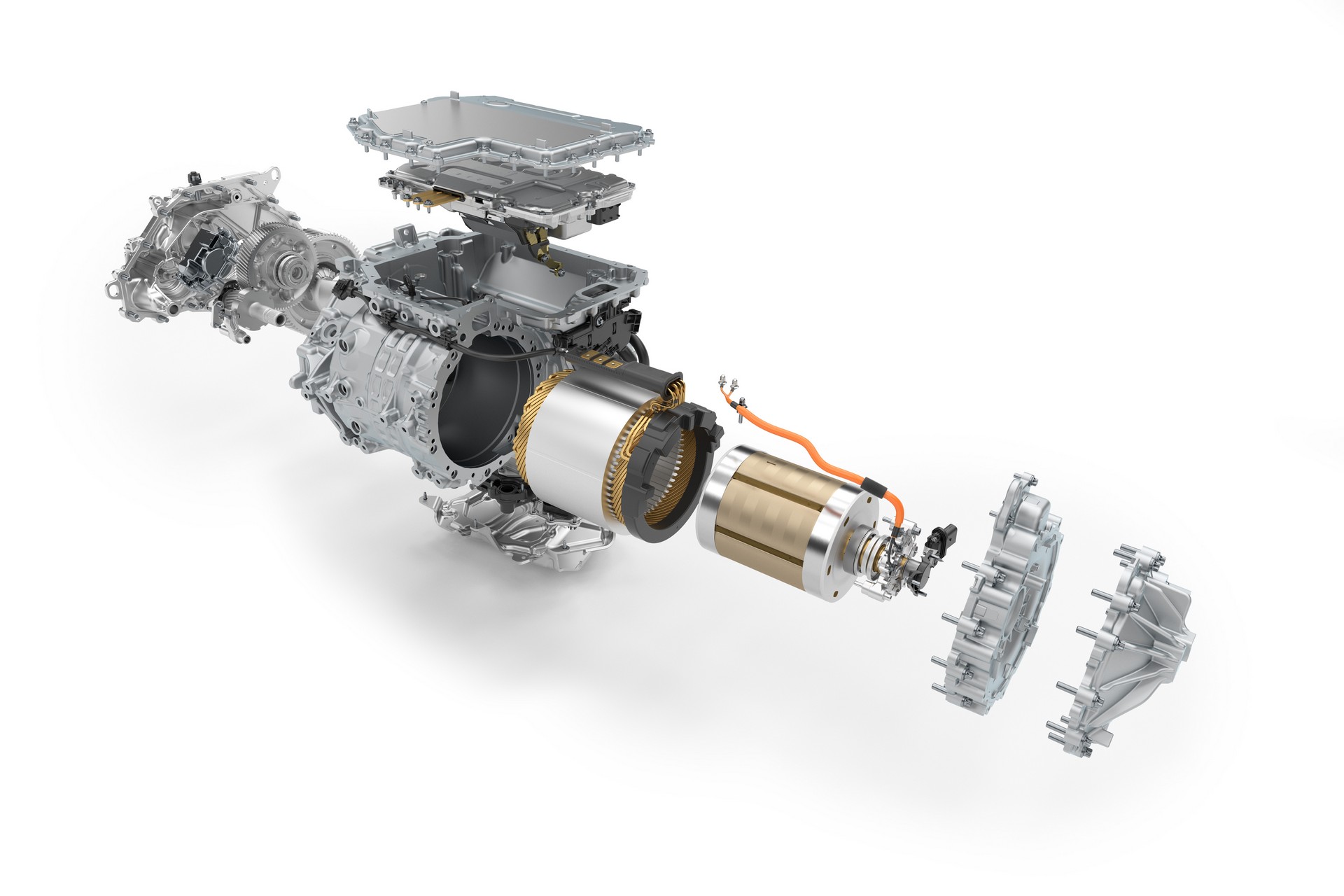

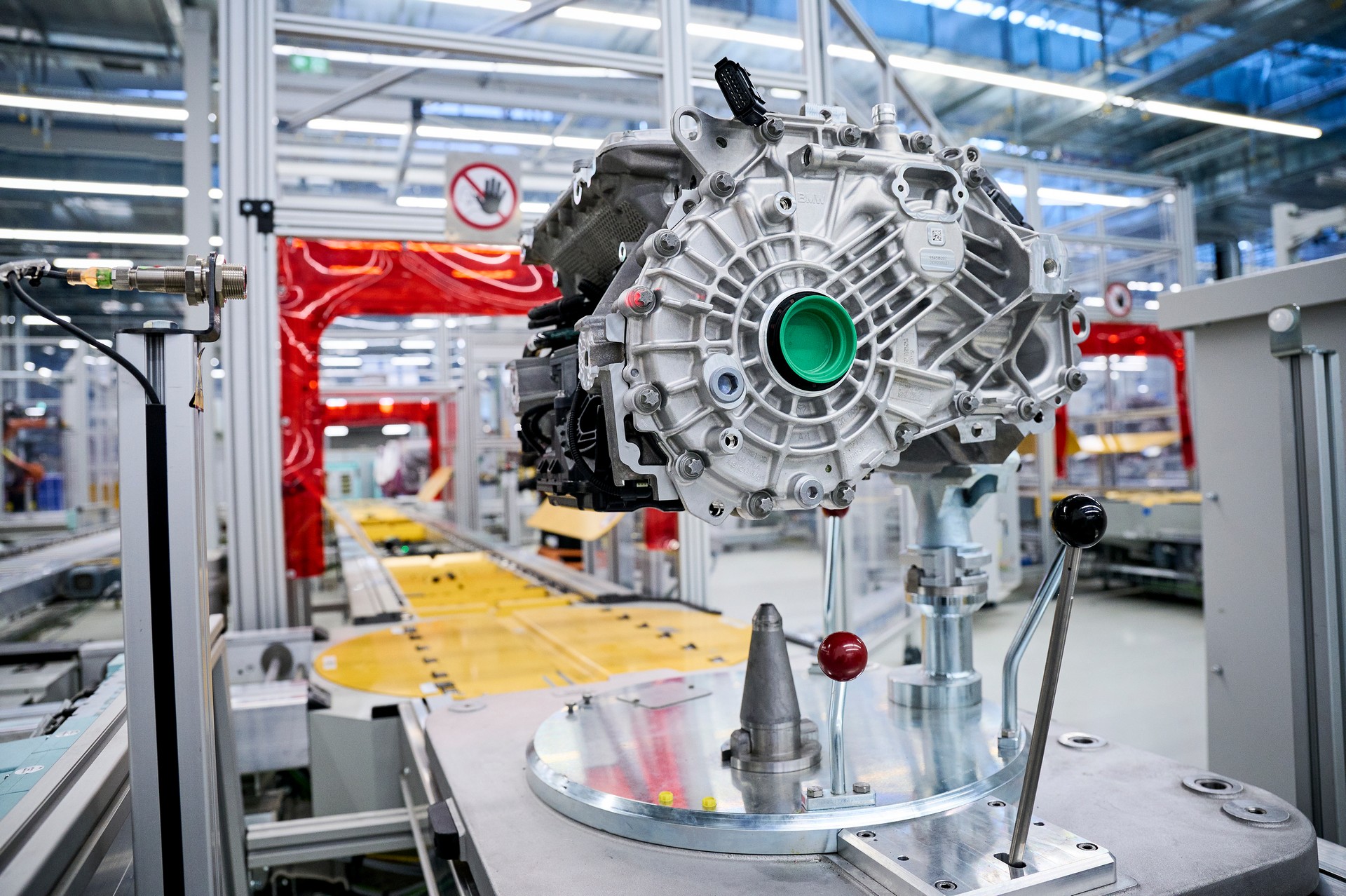

The facility has been operating more than 40 years and one out of every two BMW Group vehicles around the world today has a powertrain built at the Steyr site. In readying it for electric powertrain production, BMW will establish a new two-story production hall that will house two assembly lines for electric powertrains and transmissions.

This building will also be used for manufacturing power electronics with clean room technology. A second new building will also expand the site’s logistics areas and all up, the upgrades will expand total production area by about 60,000 square meters and cost BMW roughly €710 million ($747 million) by 2030.

Driven: 2022 BMW i4 eDrive40 Shows Carmaker Is Serious About EVs

The next-generation electric powertrains to be produced at the Steyr site will be developed entirely on site, accounting for an additional €230 million ($242 million) investment.

“The manufacturing industry is an important partner when it comes to strengthening Austria as a business hub, creating jobs and driving innovation,” Austrian Chancellor Karl Nehammer said at an event celebrating the announcement. “It is an enabler for an effective and sustainably successful fight against climate change. In all these respects, BMW Group in Austria is already today a model company. It functions like a powerful engine for a sustainable future for our country, proving once again that climate protection and economic growth are not contradictory, but can go together.”

BMW will ultimately produce more than 600,000 electric powertrains at the factory each year while still maintaining production of diesel and petrol engines. Approximately half of the site’s 4,400 employees will be working on electromobility by 2030. The factory will also source 100 per cent of its energy requirements from renewable sources no later than 2025 through the use of green power and heat from regional biomass.