- Fully automated car plants could arrive by 2030 led by Chinese brands.

- Automakers want efficiency while human workers worry about job security.

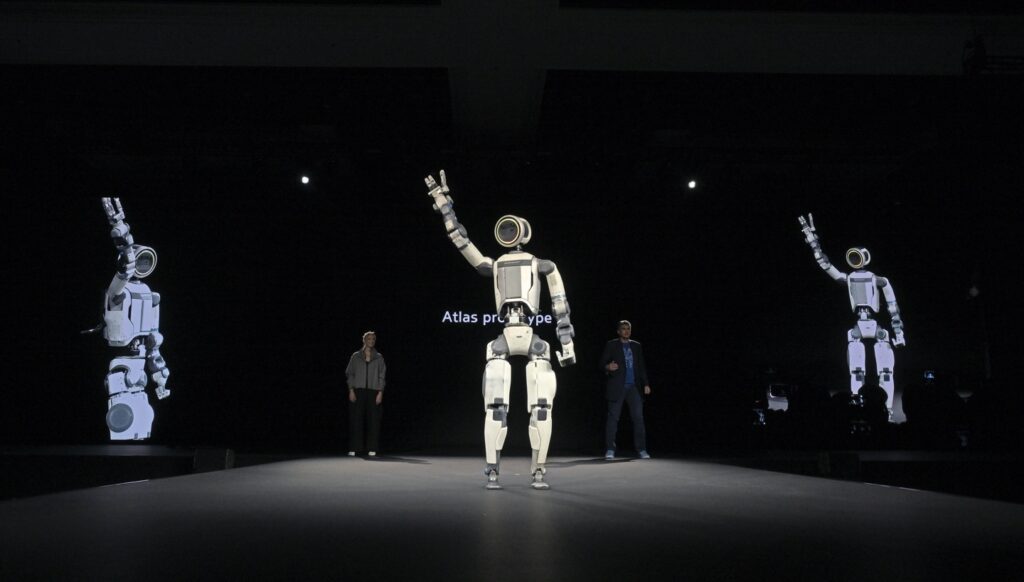

- Hyundai recently said it will employee robots at its Georgia plant by 2028.

Machines have been helping humans build new cars faster and more accurately for decades, but that relationship is about to shift dramatically. Some industry experts now believe we’re just five years away from a fully automated car factory with no humans at all.

Those experts refer to wholly robot-staffed factories as “dark” plants, with analysts from Gartner and Warburg Research predicting that a Chinese automaker will likely be the first to eradicate humans from the workforce, possibly as soon as 2030.

Related: America Asked For More Manufacturing Jobs, So Hyundai’s Sending Humanoid Robots

But other analysts think the US car industry will only be a small step behind. According to Auto News, American carmakers could also achieve fully automated production lines before 2030, though with people still involved in broader plant operations. Rather than eliminating all roles, the shift would primarily affect the assembly process itself.

Hyundai’s Robot Ambitions

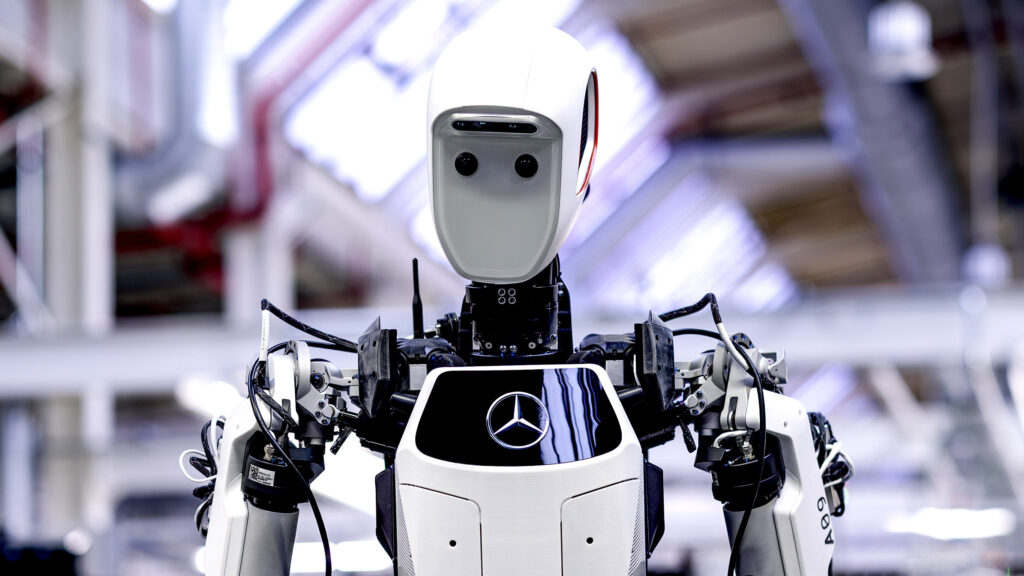

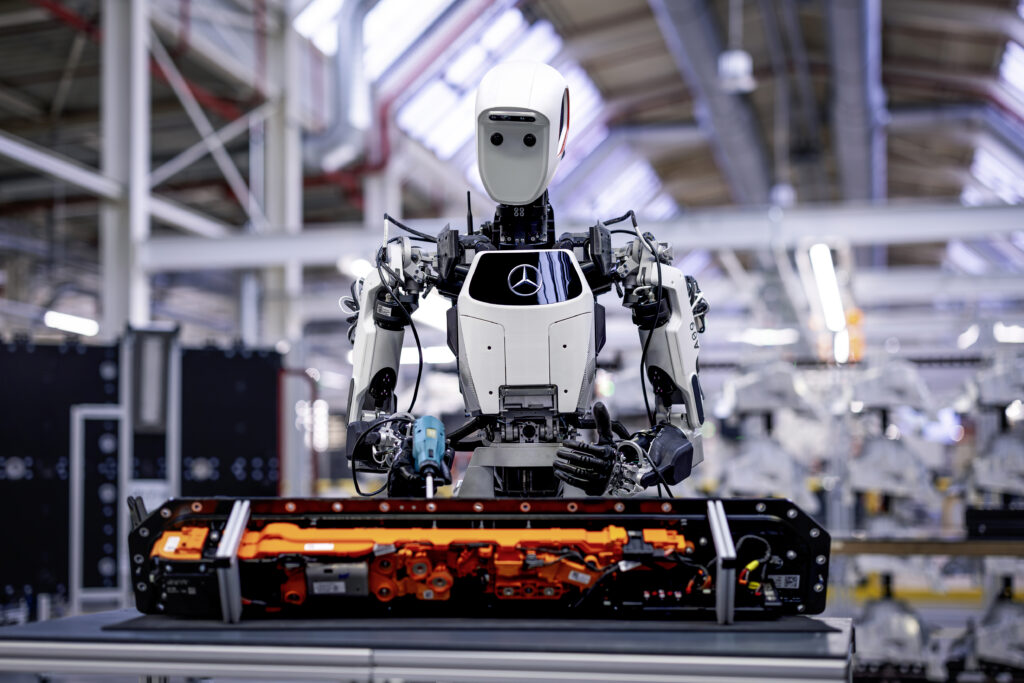

This isn’t a flight of fantasy. Hyundai is already planning to deploy Boston Dynamics humanoid robots at its Georgia plant starting in 2028, while Mercedes is testing similar ideas on a smaller scale.

Tesla is also building its own robots and you can bet every other large-scale automaker with a desire to trim its costs – which is all of them – is also interested in the tech.

Because from an automaker’s point of view, the idea of a robot workforce sounds fantastic. They don’t need to sleep, take vacations, or even toilet breaks, and they don’t demand health insurance and pension contributions. Consulting firm Accenture says advanced automation could cut costs and time to market by up to 50 percent, the report says.

Adapting Cars for a Machine-First Future

This coming technical shift is also changing how cars are designed, Auto News explains. Parts might be added to a shell in a different order to better suit the robots and complicated parts like wiring harnesses – one of the few items currently not handled by robots because they’re tricky to install – might be split or embedded into body panels.

That’s the upside, while unions and savvy workers can easily see the potential downsides for entire communities when thousands of people are no longer needed. According to experts, humans will still be needed for maintenance, logistics, quality control, software oversight, and system design, suggesting many jobs will be transferred, rather than lost.

Still, job losses will be unavoidable, and you can bet the UAW and other unions are unlikely to accept them quietly. As automation ramps up, so will the tension between technological advancement and workforce preservation.