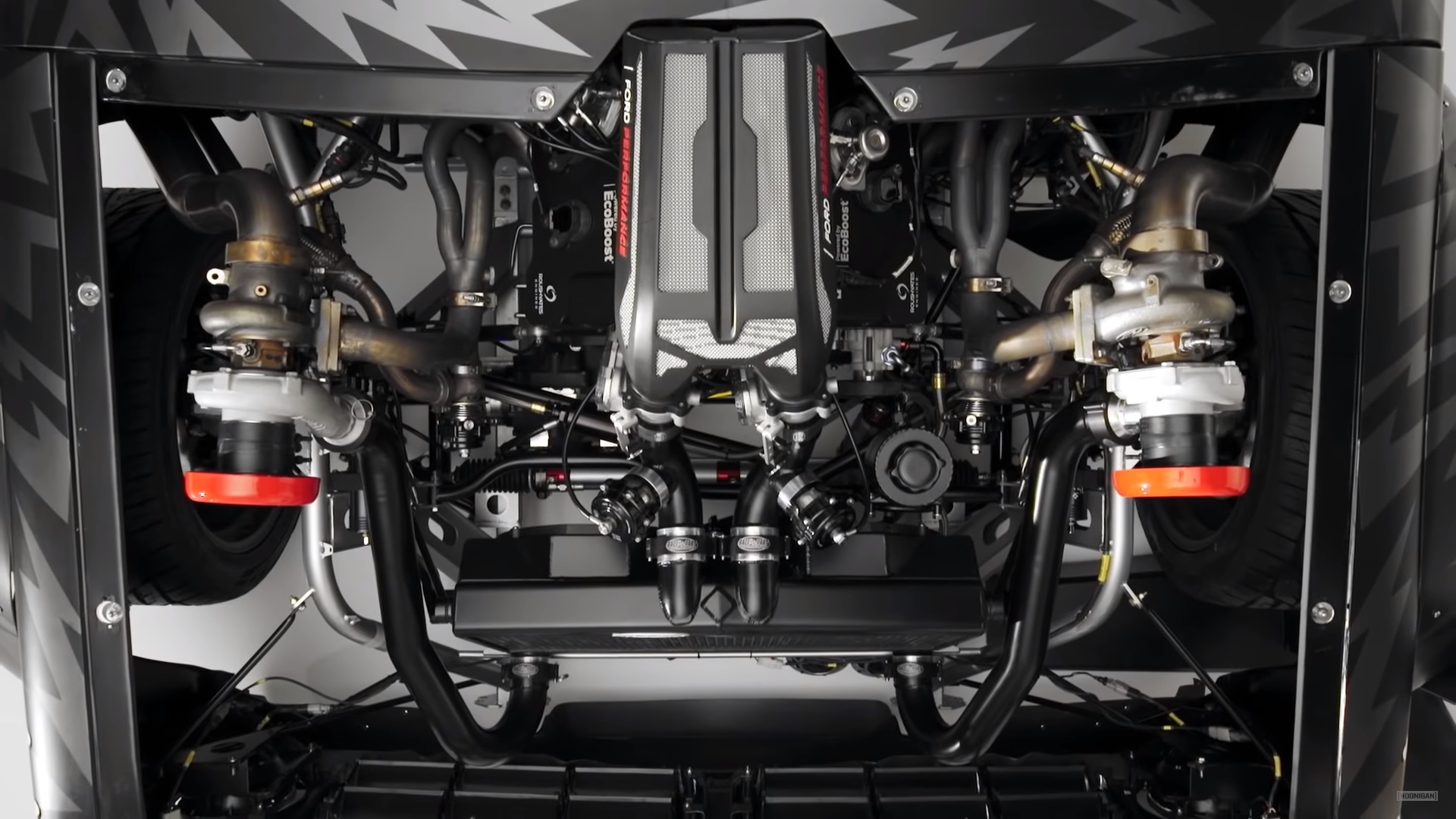

The Hoonitruck is easily one of 2018’s most special builds, as it combines Ken Block’s love affair with Ford pickup trucks with outrageous specs. The devil, however, is in the details, and more specifically at the gorgeous aluminum intake manifold that sits proudly on top of the twin turbo V6.

Ford Performance engineers worked together with a team of research engineers in Europe in designing the part and conducting structural analysis. With the help of RWTH Aachen’s Digital Additive Production Institute in Germany, the team was able to 3D-print a very intricate aluminum intake manifold that sends air from the turbos to the cylinders.

3D printing (also known as additive manufacturing) offers significant design flexibility, helping in improving performance and reducing weight. The whole process of building the Hoonitruck’s manifold took five days, with the finished part weighing almost 6 kg (13.2lbs).

“We are fortunate to have access to incredible technology, but this was one project that pushed us – and our computing power – to the absolute limit. The manifold has a complex, web‑like structure that couldn’t be made using traditional manufacturing methods. We ended up dissolving the support systems in acid,” said Raphael Koch, engineer, Advanced Materials and Processes, Ford of Europe.

“I think Ford did an exceptional job. This is my favorite part of the ‘Hoonitruck’. You could not have made it any other way,” said Ken Block.

The Hoonitruck is powered by a modified twin-turbo 3.5-liter V6 Ecoboost from the Ford GT Le Mans racer, producing an immense 914 HP and 702lb-ft of peak torque. Its custom body is made out of military-grade aluminum and it even has a trailer hitch that was put in good use during the latest Gymkhana Ten video.